Page 212 - Lindens Handbook of Batteries

P. 212

9.6 PRIMARY BATTERIES

is the premium grade of the zinc chloride line. This cell is composed mainly of an electrolyte of

zinc chloride with perhaps a small amount of ammonium chloride, usually not exceeding 1% of the

cathode weight. The cathode uses electrolytic manganese dioxide (EMD) exclusively. These cells

use paper separators coated with cross-linked or modified starches, which enhance their stability

in the electrolyte. Many manufacturers use proprietary separators in almost all their zinc-carbon

type batteries. This battery type is recommended when good performance is desired but at higher

cost. It also has improved low-temperature characteristics and reduced electrolyte leakage.

In general, the higher the grade or class of zinc-carbon batteries, the lower the cost per minute of

service. The price difference between classes is about 10 to 25%, but the performance difference can

be from 30 to 100% in favor of the higher grades depending upon the application drain.

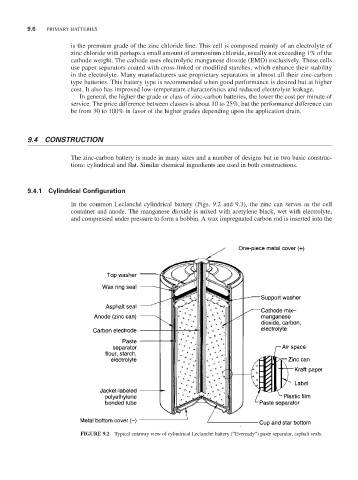

9.4 CONSTRUCTION

The zinc-carbon battery is made in many sizes and a number of designs but in two basic construc-

tions: cylindrical and flat. Similar chemical ingredients are used in both constructions.

9.4.1 Cylindrical Configuration

In the common Leclanché cylindrical battery (Figs. 9.2 and 9.3), the zinc can serves as the cell

container and anode. The manganese dioxide is mixed with acetylene black, wet with electrolyte,

and compressed under pressure to form a bobbin. A wax impregnated carbon rod is inserted into the

FIGURE 9.2 Typical cutaway view of cylindrical Leclanché battery (“Eveready”) paste separator, asphalt seals.