Page 215 - Lindens Handbook of Batteries

P. 215

ZINC-CARBON BATTERIES—LECLANCHÉ AND ZINC CHLORIDE CELL SYSTEMS 9.9

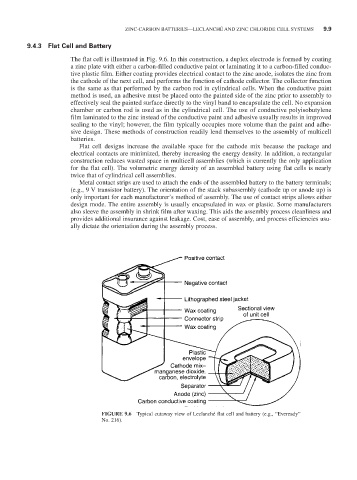

9.4.3 Flat Cell and Battery

The flat cell is illustrated in Fig. 9.6. In this construction, a duplex electrode is formed by coating

a zinc plate with either a carbon-filled conductive paint or laminating it to a carbon-filled conduc-

tive plastic film. Either coating provides electrical contact to the zinc anode, isolates the zinc from

the cathode of the next cell, and performs the function of cathode collector. The collector function

is the same as that performed by the carbon rod in cylindrical cells. When the conductive paint

method is used, an adhesive must be placed onto the painted side of the zinc prior to assembly to

effectively seal the painted surface directly to the vinyl band to encapsulate the cell. No expansion

chamber or carbon rod is used as in the cylindrical cell. The use of conductive polyisobutylene

film laminated to the zinc instead of the conductive paint and adhesive usually results in improved

sealing to the vinyl; however, the film typically occupies more volume than the paint and adhe-

sive design. These methods of construction readily lend themselves to the assembly of multicell

batteries.

Flat cell designs increase the available space for the cathode mix because the package and

electrical contacts are minimized, thereby increasing the energy density. In addition, a rectangular

construction reduces wasted space in multicell assemblies (which is currently the only application

for the flat cell). The volumetric energy density of an assembled battery using flat cells is nearly

twice that of cylindrical cell assemblies.

Metal contact strips are used to attach the ends of the assembled battery to the battery terminals;

(e.g., 9 V transistor battery). The orientation of the stack subassembly (cathode up or anode up) is

only important for each manufacturer’s method of assembly. The use of contact strips allows either

design mode. The entire assembly is usually encapsulated in wax or plastic. Some manufacturers

also sleeve the assembly in shrink film after waxing. This aids the assembly process cleanliness and

provides additional insurance against leakage. Cost, ease of assembly, and process efficiencies usu-

ally dictate the orientation during the assembly process.

FIGURE 9.6 Typical cutaway view of Leclanché flat cell and battery (e.g., “Eveready”

No. 216).