Page 329 - MEMS and Microstructures in Aerospace Applications

P. 329

Osiander / MEMS and microstructures in Aerospace applications

323

Material Selection for Applications of MEMS

13.2

7.1,

13.4

17.3

4.5

3.3

8.1

1

25

1

12

Thermal

1.4

235

1,200

25

80

91

2,000

490

33

178

485

2,480

9,000

to

400

130

2,100

660

251

850

Knoop

8,500

7,500

0.228

0.208

Strain

7.22

0.14

0.15

11.79

0.62

0.75

0.54

0.31

Specific

0.303

0.21

0.11

0.23

0.06

15.14

1.62

0.12

0.28

0.5

s/r Thermal Conductivity Hardness Tolerance, Strength, (10 26 /K) Expansion (W/m/K) (kg/mm 2 ) (vMPa) s 3/2 /E (MN*m/kg) 2.35 150 to 850 1.5 1.7 1,100 2.8 150 to 1,070 0.43 0.77 1,275 0.55 1.38 820 0.43 0.45 0.8 19 3,486 0.1 0.3 DK3181_c014 Final Proof page 323 1.9.2005

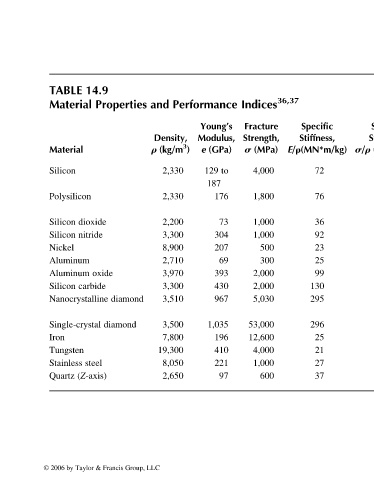

Specific Stiffness, E/r(MN*m/kg) 72 76 36 92 23 25 99 130 295 296 25 21 27 37

Indices 36,37 Fracture Strength, (MPa) s 4,000 1,800 1,000 1,000 500 300 2,000 2,000 5,030 53,000 12,600 4,000 1,000 600

Performance Young’s Modulus, (GPa) e to 129 187 176 73 304 207 69 393 430 967 1,035 196 410 221 97

and Density, (kg/m 3 ) r 2,330 2,330 2,200 3,300 8,900 2,710 3,970 3,300 3,510 3,500 7,800 19,300 8,050 2,650

Properties diamond diamond

14.9 dioxide nitride oxide carbide steel (Z-axis) © 2006 by Taylor & Francis Group, LLC

TABLE Material Material Silicon Polysilicon Silicon Silicon Nickel Aluminum Aluminum Silicon Nanocrystalline Single-crystal Iron Tungsten Stainless Quartz