Page 330 - MEMS and Microstructures in Aerospace Applications

P. 330

Osiander / MEMS and microstructures in Aerospace applications

323

Material Selection for Applications of MEMS DK3181_c014 Final Proof page 323 1.9.2005 12:47pm

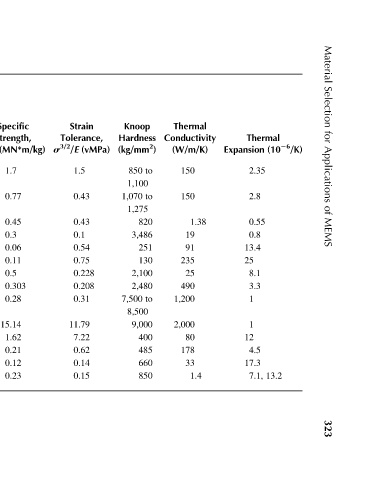

(10 26 /K)

Thermal 2.35 2.8 0.55 0.8 8.1 3.3 4.5 13.2 7.1,

Expansion 13.4 25 1 1 12 17.3

Thermal Conductivity (W/m/K) 150 150 1.38 19 91 235 25 490 1,200 2,000 80 178 33 1.4

Knoop Hardness (kg/mm 2 ) to 850 1,100 to 1,070 1,275 820 3,486 251 130 2,100 2,480 to 7,500 8,500 9,000 400 485 660 850

Strain Tolerance, (vMPa) s 3/2 /E 1.5 0.43 0.43 0.1 0.54 0.75 0.228 0.208 0.31 11.79 7.22 0.62 0.14 0.15

Specific Strength, (MN*m/kg) 1.7 0.77 0.45 0.3 0.06 0.11 0.5 0.303 0.28 15.14 1.62 0.21 0.12 0.23

s/r

Specific Stiffness, E/r(MN*m/kg) 72 76 36 92 23 25 99 130 295 296 25 21 27 37

Indices 36,37 Fracture Strength, (MPa) s 4,000 1,800 1,000 1,000 500 300 2,000 2,000 5,030 53,000 12,600 4,000 1,000 600

Performance Young’s Modulus, (GPa) e to 129 187 176 73 304 207 69 393 430 967 1,035 196 410 221 97

and Density, (kg/m 3 ) r 2,330 2,330 2,200 3,300 8,900 2,710 3,970 3,300 3,510 3,500 7,800 19,300 8,050 2,650

Properties diamond diamond

14.9 dioxide nitride oxide carbide steel (Z-axis) © 2006 by Taylor & Francis Group, LLC

TABLE Material Material Silicon Polysilicon Silicon Silicon Nickel Aluminum Aluminum Silicon Nanocrystalline Single-crystal Iron Tungsten Stainless Quartz