Page 88 - MEMS and Microstructures in Aerospace Applications

P. 88

Osiander / MEMS and microstructures in Aerospace applications DK3181_c004 Final Proof page 76 25.8.2005 3:40pm

76 MEMS and Microstructures in Aerospace Applications

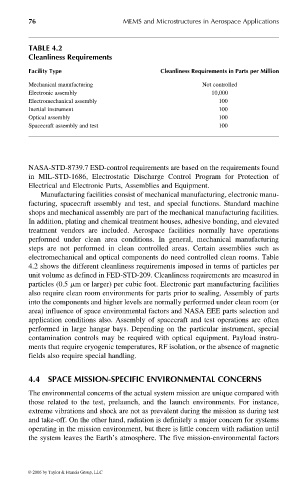

TABLE 4.2

Cleanliness Requirements

Facility Type Cleanliness Requirements in Parts per Million

Mechanical manufacturing Not controlled

Electronic assembly 10,000

Electromechanical assembly 100

Inertial instrument 100

Optical assembly 100

Spacecraft assembly and test 100

NASA-STD-8739.7 ESD-control requirements are based on the requirements found

in MIL-STD-1686, Electrostatic Discharge Control Program for Protection of

Electrical and Electronic Parts, Assemblies and Equipment.

Manufacturing facilities consist of mechanical manufacturing, electronic manu-

facturing, spacecraft assembly and test, and special functions. Standard machine

shops and mechanical assembly are part of the mechanical manufacturing facilities.

In addition, plating and chemical treatment houses, adhesive bonding, and elevated

treatment vendors are included. Aerospace facilities normally have operations

performed under clean area conditions. In general, mechanical manufacturing

steps are not performed in clean controlled areas. Certain assemblies such as

electromechanical and optical components do need controlled clean rooms. Table

4.2 shows the different cleanliness requirements imposed in terms of particles per

unit volume as defined in FED-STD-209. Cleanliness requirements are measured in

particles (0.5 mm or larger) per cubic foot. Electronic part manufacturing facilities

also require clean room environments for parts prior to sealing. Assembly of parts

into the components and higher levels are normally performed under clean room (or

area) influence of space environmental factors and NASA EEE parts selection and

application conditions also. Assembly of spacecraft and test operations are often

performed in large hangar bays. Depending on the particular instrument, special

contamination controls may be required with optical equipment. Payload instru-

ments that require cryogenic temperatures, RF isolation, or the absence of magnetic

fields also require special handling.

4.4 SPACE MISSION-SPECIFIC ENVIRONMENTAL CONCERNS

The environmental concerns of the actual system mission are unique compared with

those related to the test, prelaunch, and the launch environments. For instance,

extreme vibrations and shock are not as prevalent during the mission as during test

and take-off. On the other hand, radiation is definitely a major concern for systems

operating in the mission environment, but there is little concern with radiation until

the system leaves the Earth’s atmosphere. The five mission-environmental factors

© 2006 by Taylor & Francis Group, LLC