Page 90 -

P. 90

MEMS Fabrication 3-45

SiO mask

2

(A)

SiO 2

Si

(B)

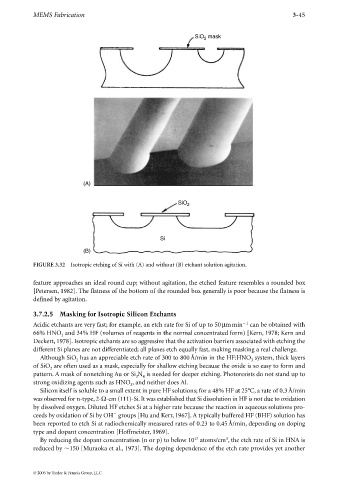

FIGURE 3.32 Isotropic etching of Si with (A) and without (B) etchant solution agitation.

feature approaches an ideal round cup; without agitation, the etched feature resembles a rounded box

[Petersen, 1982]. The flatness of the bottom of the rounded box generally is poor because the flatness is

defined by agitation.

3.7.2.5 Masking for Isotropic Silicon Etchants

Acidic etchants are very fast; for example, an etch rate for Si of up to 50µmmin 1 can be obtained with

66% HNO and 34% HF (volumes of reagents in the normal concentrated form) [Kern, 1978; Kern and

3

Deckert, 1978]. Isotropic etchants are so aggressive that the activation barriers associated with etching the

different Si planes are not differentiated; all planes etch equally fast, making masking a real challenge.

Although SiO has an appreciable etch rate of 300 to 800Å/min in the HF:HNO system, thick layers

3

2

of SiO are often used as a mask, especially for shallow etching because the oxide is so easy to form and

2

pattern. A mask of nonetching Au or Si N is needed for deeper etching. Photoresists do not stand up to

3

4

strong oxidizing agents such as HNO , and neither does Al.

3

Silicon itself is soluble to a small extent in pure HF solutions; for a 48% HF at 25°C, a rate of 0.3Å/min

was observed for n-type, 2-Ω-cm (111)-Si. It was established that Si dissolution in HF is not due to oxidation

by dissolved oxygen. Diluted HF etches Si at a higher rate because the reaction in aqueous solutions pro-

ceeds by oxidation of Si by OH groups [Hu and Kerr, 1967]. A typically buffered HF (BHF) solution has

been reported to etch Si at radiochemically measured rates of 0.23 to 0.45Å/min, depending on doping

type and dopant concentration [Hoffmeister, 1969].

17

3

By reducing the dopant concentration (n or p) to below 10 atoms/cm , the etch rate of Si in HNA is

reduced by

150 [Muraoka et al., 1973]. The doping dependence of the etch rate provides yet another

© 2006 by Taylor & Francis Group, LLC