Page 108 - Machinery Component Maintenance

P. 108

Machinery Foundations and Grouting 91

and at least two ft into the undamaged concrete below. In addition, holes

can be drilled in the remaining part of the foundation shoulders at such

angles so as to cross below the oil pan at an elevation of approximately

two to three ft below the pan or trough. Afterward, additional horizontal

reinforcing steel can be installed and wired to the vertical members

which were earlier cemented into the good concrete with an epoxy adhe-

sive. The purpose of the new reinforcing steel is to transfer as much load

as possible to an area where the concrete was unaffected by oil dcgrada-

tion.

Pressure-Injection Regrouting

Pressure-grouting is a repair process whereby equipment can be reaf-

fixed on the foundation without lifting the equipment, without completely

chipping away the old grout, and without repositioning and complete re-

grouting. Pressure grouting should not, however, be considered a pana-

cea. Nevertheless, when properly used it can be a valuable tool.

Shoulder Removal Method

Pressure-injection regrouting techniques offer equipment operators im-

portant advantages of reduced downtime, lower labor costs, and less rev-

enue lost from idle equipment. These techniques make possible satisfac-

tory and long life regrouts with machine downtime at a minimum.

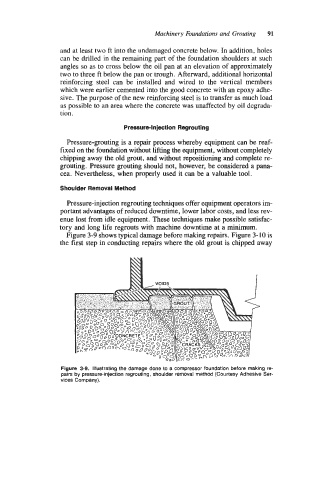

Figure 3-9 shows typical damage before making repairs. Figure 3-10 is

the first step in conducting repairs where the old grout is chipped away

Figure 3-9. Illustrating the damage done to a compressor foundation before making re-

pairs by pressure-injection regrouting, shoulder removal method (Courtesy Adhesive Ser-

vices Company).