Page 114 - Machinery Component Maintenance

P. 114

Machinery Foundations and Grouting 97

/

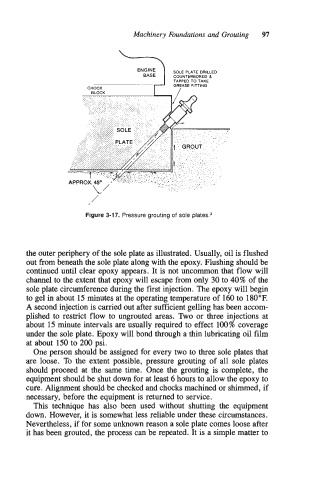

Figure 3-17. Pressure grouting of sole plate^.^

the outer periphery of the sole plate as illustrated. Usually, oil is flushed

out from beneath the sole plate along with the epoxy. Flushing should be

continued until clear epoxy appears. It is not uncommon that flow will

channel to the extent that epoxy will escape from only 30 to 40% of the

sole plate circumference during the first injection. The epoxy will begin

to gel in about 15 minutes at the operating temperature of 160 to 180°F.

A second injection is carried out after sufficient gelling has been accom-

plished to restrict flow to ungrouted areas. Two or three injections at

about 15 minute intervals are usually required to effect 100% coverage

under the sole plate. Epoxy will bond through a thin lubricating oil film

at about 150 to 200 psi.

One person should be assigned for every two to three sole plates that

are loose. To the extent possible, pressure grouting of all sole plates

should proceed at the same time. Once the grouting is complete, the

equipment should be shut down for at least 6 hours to allow the epoxy to

cure. Alignment should be checked and chocks machined or shimmed, if

necessary, before the equipment is returned to service.

This technique has also been used without shutting the equipment

down. However, it is somewhat less reliable under these circumstances.

Nevertheless, if for some unknown reason a sole plate comes loose after

it has been grouted, the process can be repeated. It is a simple matter to