Page 124 - Machinery Component Maintenance

P. 124

Machinery Foundations and Grouting 107

adaptor that matches the irregular-shaped pump baseplate to the top of

the irregular-shaped concrete. The ideal pump baseplate installation is

one that is 100 percent supported by the grout, Le., all leveling devices

are removed.

This ideal pump baseplate installation can be achieved by using the

method illustrated in Figure 3-23. Jack screws located on both sides of

each anchor bolt are used to elevate the pump baseplate to the level posi-

tion, while the anchor bolt lightly holds the baseplate firm. It may not be

necessary to use both jack screws if the baseplate is flat, but both are

required if an attempt is made to influence the flatness of machined sup-

port surfaces. Notice that circular plates cut from 2.0-in. to 2.5-in. diam-

eter steel-bar stock, approximately 0.250-in. thick, are used to prevent

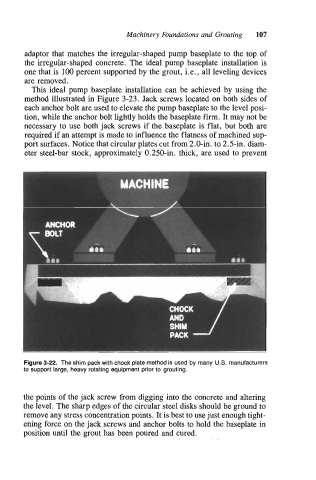

Figure 3-22. The shim pack with chock plate method is used by many US. manufacturers

to support large, heavy rotating equipment prior to grouting.

the points of the jack screw from digging into the concrete and altering

the level. The sharp edges of the circular steel disks should be ground to

remove any stress concentration points. It is best to use just enough tight-

ening force on the jack screws and anchor bolts to hold the baseplate in

position until the grout has been poured and cured.