Page 17 - Machinery Component Maintenance

P. 17

4 Machinery Component Maintenance and Repair

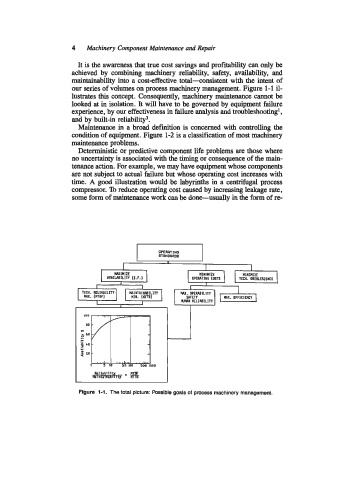

It is the awareness that true cost savings and profitability can only be

achieved by combining machinery reliability, safety, availability, and

maintainability into a cost-effective total-consistent with the intent of

our series of volumes on process machinery management. Figure 1-1 il-

lustrates this concept. Consequently, machinery maintenance cannot be

looked at in isolation. It will have to be governed by equipment failure

experience, by our effectiveness in failure analysis and troubleshooting',

and by built-in reliability3.

Maintenance in a broad definition is concerned with controlling the

condition of equipment. Figure 1-2 is a classification of most machinery

maintenance problems.

Deterministic or predictive component life problems are those where

no uncertainty is associated with the timing or consequence of the main-

tenance action. For example, we may have equipment whose components

are not subject to actual failure but whose operating cost increases with

time. A good illustration would be labyrinths in a centrifugal process

compressor. To reduce operating cost caused by increasing leakage rate,

some form of maintenance work can be done-usually in the form of re

I OPERRTINB I

STFINDQRDS

AVAILABILITY (S.F.) OPERATING COSTS TECH. OBSOLESCENCE

Eux. (MTBF) MlN. (KITR) RX. EFFICIENCY

Figure 1-1. The total picture: Possible goals of process machinery management.