Page 20 - Machinery Component Maintenance

P. 20

6 Machinery Component Maintenance and Repair

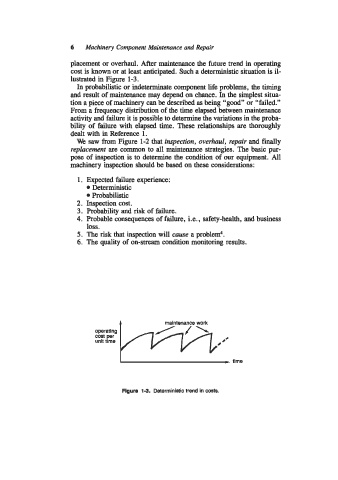

placement or overhaul. After maintenance the future trend in operating

cost is known or at least anticipated. Such a deterministic situation is il-

lustrated in Figure 1-3.

In probabilistic or indeterminate component life problems, the timing

and result of maintenance may depend on chance. In the simplest situa-

tion a piece of machinery can be described as being “good” or “failed.”

From a frequency distribution of the time elapsed between maintenance

activity and failure it is possible to determine the variations in the proba-

bility of failure with elapsed time. These relationships are thoroughly

dealt with in Reference 1.

Wi: saw from Figure 1-2 that inspection, overhaul, repair and finally

replacement are common to all maintenance strategies. The basic pur-

pose of inspection is to determine the condition of our equipment. All

machinery inspection should be based on these considerations:

1. Expected failure experience:

Deterministic

Probabilistic

2. Inspection cost.

3. Probability and risk of failure.

4. Probable consequences of failure, Le., safety-health, and business

loss.

5. The risk that inspection will cuuse a problem4.

6. The quality of on-stream condition monitoring results.

I : time

Figure 1-3. Deterministic trend in costs.