Page 179 - Machinery Component Maintenance

P. 179

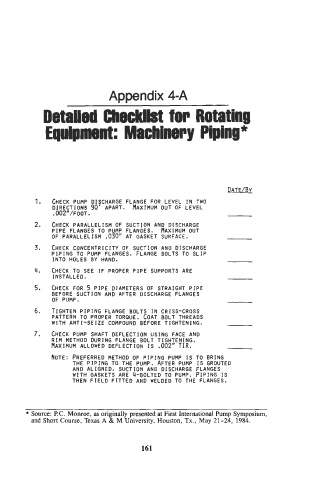

Appendix 4-A

Detailed Checklist for Rotatina

- - ______ __ __ - -~~

Equipment: Machinery Pipingg

DATE/BY

1. CHECK PUMP DISCHARGE FLANGE FOR LEVEL IN TWO

DIRECTIONS 90' APART. MAXIMUM OUT OF LEVEL

,002"/FOOT.

2. CHECK PARALLELISM OF SUCTION AND DISCHARGE

PIPE FLANGES TO PUMP FLANGES. MAXIMUM OUT

OF PARALLELISM .030" AT GASKET SURFACE.

3, CHECK CONCENTRICITY OF SUCTION AND DISCHARGE

PIPING TO PUMP FLANGES, FLANGE BOLTS TO SLIP

INTO HOLES BY HAND.

4, CHECK TO SEE IF PROPER PIPE SUPPORTS ARE

INSTALLED.

5. CHECK FOR 5 PIPE DIAMETERS OF STRAIGHT PIPE

BEFORE SUCTION AND AFTER DISCHARGE FLANGES

OF PUMP.

6. TIGHTEN PIPING FLANGE BOLTS IN CRISS-CROSS

PATTERN TO PROPER TORQUE, COAT BOLT THREADS

WITH ANTI-SEIZE COMPOUND BEFORE TIGHTENING.

7. CHECK PUMP SHAFT DEFLECTION USING FACE AND

RIM METHOD DURING FLANGE BOLT TIGHTENING.

MAXIMUM ALLOWED DEFLECTION IS .002" TIR.

NOTE: PREFERRED METHOD OF PIPING PUMP IS TO BRING

THE PIPING TO THE PUMP. AFTER PUMP IS GROUTED

AND ALIGNED, SUCTION AND DISCHARGE FLANGES

WITH GASKETS ARE 4-BOLTED TO PUMP, PIPING IS

THEN FIELD FITTED AND WELDED TO THE FLANGES.

* Source: P.C. Monroe, as originally presented at First international Pump Symposium,

and Short Course, Texas A & M University, Houston, Tx., May 21-24, 1984.

161