Page 185 - Machinery Component Maintenance

P. 185

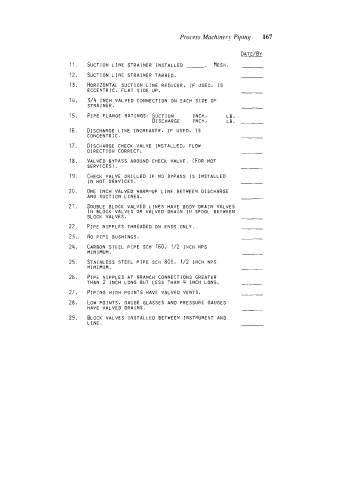

Process Machinery Piping 167

DATEIBY

11. SUCTION LINE STRAINER INSTALLED . MESH.

12. SUCTION LINE STRAINER TABBED.

13. HORIZONTAL SUCTION LINE REDUCER, IF USED, IS

ECCENTRIC, FLAT SIDE UP.

14. 3/4 INCH VALVED CONNECTION ON EACH SIDE OF

STRAINER.

15. PIPE FLANGE RATINGS: SUCTION INCH I LB.

DISCHARGE INCH. LB.

16. DISCHARGE LINE INCREASER. IF USFD, IS

CONCENTRIC.

17. DISCHARGE CHECK VALVE INSTALLED, FLOW

DIRECTION CORRECT.

18. VALVED BYPASS AROUND CHECK VALVE. (FOR HOT

SERVICES).

19. CHECK VALVE DRILLED IF NO BYPASS IS INSTALLED

IN HOT SERVICES.

20 * ONE INCH VALVED WARM-UP LINE BETWEEY DISCHARGE

AND SUCTION LINES.

21. DOUBLE BLOCK VALVED LINES HAVE BODY DRAIN VALVES

IN BLOCK VALVES OR VALVED DRAIN Ir! SPOOL BETWEEN

BLOCK VALVES I

PIPE NIPPLES THREADED ON ENDS ONLY.

22 I

23. NO PIPE BUSHINGS.

MIN IMUM .

24 I CARBON STEEL PIPE SCH 160, 1/2 INCH NPS

25 I STAINLESS STEEL PIPE SCH 80S, 1/2 INCH NPS

MINIMUM.

PIPE NIPPLES AT BRANCH CONNECTIONS GREATER

26 I

THAN 2 INCH LONG BUT LESS THAN 4 INCH LONG.

27. PIPING HIGH POINTS HAVE VALVED VENTS.

28. LOW POINTS. GAUGE GLASSES AND PRESSURE GAUGES

HAVE VALVED DRAINS.

29. BLOCK VALVES INSTALLED BETWEEN INSTRUMENT AND

LINE.