Page 208 - Machinery Component Maintenance

P. 208

190 Machinery Component Maintenance and Repair

J.

I-1

Shaft or Coupling

Measurement Surface

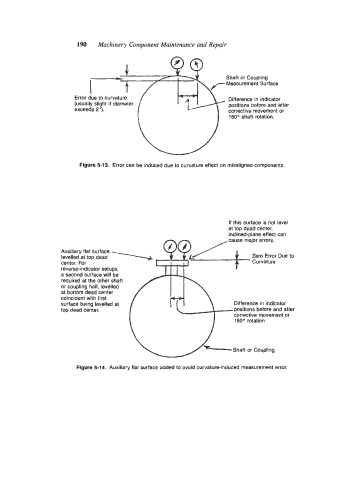

Error due to curvature Difference in indicator

(usually slight if diameter

positions before and after

exceeds 2 'I). corrective movement or

1 180° shaft rotation.

Figure 5-13. Error can be induced due to curvature effect on misaligned components.

If this surface is not level

at top dead center,

inclined-plane effect can

nn ,cause major errors.

center. For

reverse-indicator setups,

a second surface will be

required at the other shaft

or coupling half, levelled

at bottom dead center

coincident with first

surface being levelled at Difference in indicator

top dead center. positions before and after

corrective movement or

1 80° rotation

Figure 5-14. Auxiliary flat surface added to avoid curvature-induced measurement error.