Page 48 - Machinery Component Maintenance

P. 48

Maintenance Organization and Control for Multi-Plant Corporations 33

formed on a planned basis, actual plant startup delays due to the central

stocking depot concept are rare.

By careful analysis on ordering of initial spares and the central depot

concept, major corporations have been able to lower the investment in

spares (expressed as a percentage of equipment investment) from approx-

imately 5 % a few years back to under 3 % on new plants.

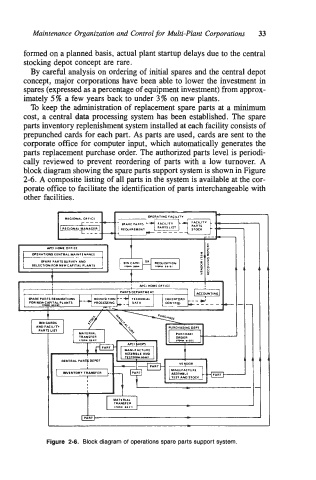

To keep the administration of replacement spare parts at a minimum

cost, a central data processing system has been established. The spare

parts inventory replenishment system installed at each facility consists of

prepunched cards for each part. As parts are used, cards are sent to the

corporate office for computer input, which automatically generates the

parts replacement purchase order. The authorized parts level is periodi-

cally reviewed to prevent reordering of parts with a low turnover. A

block diagram showing the spare parts support system is shown in Figure

2-6. A composite listing of all parts in the system is available at the cor-

porate office to facilitate the identification of parts interchangeable with

other facilities.

-

~~~ ~~

Figure 2-6. Block diagram of operations spare parts support system.