Page 55 - Machinery Component Maintenance

P. 55

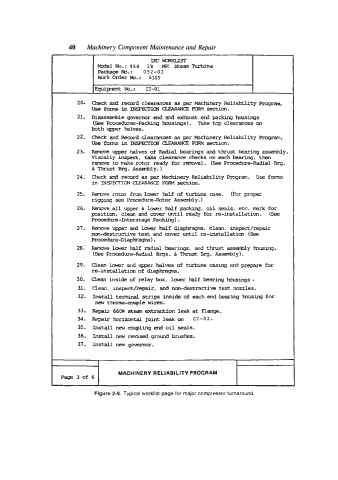

40 Machinery Component Maintenance and Repair

IRcknuuJsT

We1 No.: 9EH 1B MH Sean Wine

Package No.: 052-02

Work Order No.: 6305

1W-t No.: CT-01 I

20. ckck ad record clearances as per Machinery Reliability progran.

Use farms in INSPBXfcXJ aEUUNrZ FORM section.

21. Disassemble governor end and exhaust erd packing hsi-gs

(see h-oadures-packirg kusings). Take top clearances on

bth upper blves.

22. mck and Record clearances as pr Machinery Reliability Program.

Use fom in INSPElXtoN UZUUNCE section.

23. RBnnre upper halves of Radial bearings and thrust bearing assenbly.

Visually inspect , take clearance cM on each bearing, thzn

r-e to make rotor ready for rem-1. (See h-ocedure-Radial Brg.

6 Thrust Brg. AsseTlbly.)

24. Cteck and recnrd as per Maw Reliability Progran. Use fom

in mSPDc??oN m C € FOIW section.

25 - mve rotor fran 1-r half of turbine case. (For propex

rigging see Pnredure-Rotor Assa-bly.)

26. Rarove all upper C lower half padcirq. oil seals, etc. mk for

position. clean and cover until ready for re-installation. (Set

--Interstage Fadung).

27. Parove upper and lower half diaphragm. clean, inspect/repir

procedure-Diaphragms ) .

non4estructive test and CDVer until re-installation (.%e

28 : Renwe laver half radial bearings, and tkust assehly busmg.

(.See procedure-mal Brgs. 6 Thrust Brg. Assenbly).

29. Clean lower and upper halves of turbme cas- and prepare for

re-installation of diaphraqs.

-

30. Qean inside of relay bs. lower Mf bear- hn~~ings

31. Clean, inspecthepair, and non-destractive test mtzles.

32. Install tenninal strips inside of each end bearirg bus- for

new them-omple wires.

33. kpau 660# stean extraction leak at flange.

CT-02 -

34. Repair hxizontal joint leak cm

35. Install new coupling end oil seals.

36. Install new revised grod brusks.

37. ine-all new governor.

MACHINERY RELIABILITY PROGRAM

-3of6

Figure 2-8. Typical worklist page for major compressor turnaround.