Page 275 - Making PIC Microcontroller Instruments and Controllers

P. 275

2t. ll| AntFrcnL HOnEO|.: A l ElE SIIRFACE tllAl SIAYS IEVEI

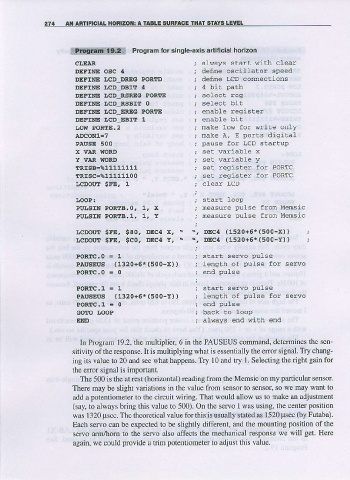

Program for single-axis a ificial horlzon

c l , s A R : a h a y s s r a ' r k : r h c l e a r

DEIINE osc 4 i defne oscillacor speed

DEFTNE I.D DREG PORTD ; dEf,NE I,CD COMECTiONS

DEFTNE LD DBI! 4 ; 4 bit Path

DEFltrE LCD RSREG PORTE ; se.Lect reg

DEFINE tcD RgalT 0 ; selecl bil

DEFTNE LCD ERIG PORTE ; enqbre regisEe-

DEFINE LCD EBII L i enable bit

r,o!{ PoRIE.2 ; make low fot write only

A!CONl=7 ; rnake A, E porCs digitat

PAUSE 500 ; pause for LCD startup

x VAR IIORD , set variabre x

Y vAR lloRD ; set variable Y

TRISB=ts11111111 ; sel ..eg:ster 'o_ DORTC

TRISC-%11111100 ; se. leg-sLer 'o. PORTC

LCDOUT SFE. 1 ; clear LCD

IOOP: ; star! loop

Pul,gtN PoRIE.O, 1, 1t ; neasure pulse from Mensic

PULSIN PoRtB.l, 1, Y ; neasure pulse fron Mensic

&cDotrr sFE, s80, DEc4 :<, \ \, DEc{ (1520+5r(s00-x)) }

ncDorrr sFE, sgo, DEc{ Y, . ", DEc{ (1520+5t(500-l)) i

PORIC.o = 1 ; start servo Pulse

PAusEUs (1320+6*(500-x)) ; lenqth of pulse for serwo

PORIC.o = 0 ; end pulse

PORI{,I = 1 ' star! servo pulse

PrusEus (1320+5*(s00-Y)) ; length of pulse for servo

POREC,I = 0

GOIO I,oOP

EIID ; ahrays end with end

In Program 19.2, the multiplier 6 in the PAUSEUS command, determines the sen'

sitivity ofthe response. It is multiplying what is essentially the error signal. Try chang-

ing its value to 20 aod see what happens. Try 10 and try l. Selecting the dght gain for

rhe error signal is imponanl.

The 500 is the at rest (horizontal) reading from the Memsic on my pafticular sensor.

There may be slight variations in the value from sensor to sensot so we may want to

add a potentiometer to the circuit wiring. That would allow us to make an adjustment

(say, to always bring this value to 500). On the servo I was using, the center position

was I 320 psec. The theoretical value for this is usually stated as 1520 psec (by Futaba).

Each servo can be expected to be slightly different, and lhe mounting position of the

servo arm/horn to the servo also affects the mechanical response we will get. Here

again, we could provide a tdm potentiometer to adjust this value.