Page 68 - Making PIC Microcontroller Instruments and Controllers

P. 68

COI{TNOLLING THE OUTPUT AND REAOITIG THE INPUT

0 to 255 for ail duee potentiometen, no matter what the actual total rcsistarce value of edlh

potentiometer. If you want to read the resistance in ohms, you must divide the reading by

255 and mulriply by the lotal resistance olthe potentiometer (Again, the potentiometer

value must be high enough so the potentiometer does not act as a shon bctween glound

and the MCU power comeclion. 5K lo 10K ohms is a good seleclion for most purposcs.)

Next, we will rcad just one of the potentioneten (the one nearest the edge of the board)

to an accuracy of 8 bits and display the results on the rightmost eight LEDS of the LED

bargraph. This potentiometer is connected to pin 2 ofthe PIC (also identified as RAo

and as pin PORTA.0). We will display the result of the value read (0 to 255) on the bar-

graph by loading the reading inlo PORTD. Since PORTD is connected to the eight

LEDS, this will automatically give us a binary rcpresentation oi the data. ln the next step,

we will display the inlormation on the LCD dispiay as alphanumeric data (which js, of

course. rnuch easier to read).

Exp.ndi4 the prcgram to not only disptay b the baryraph but also put the information on

the LCD display, we have a prcblem in that the PORTD lines are sharcd by rlre bargmph and

fie LCD display- When we run the program, we will notice ilat dEre is a backgmund noisy

blinking of the LEDS in the bargraph as the l,CD is uritten to, b t atur that is done the bar-

graph displays the data lrom the potentiometer as expected. If we had hardware and software

that could suppress thc LEDS whcn wc were writing to lhe LCD, this problem could be elim-

inaled. The opention observed demonslrates du1 the chip select line allows us to use the lines

of PORTD to control both the I-ED ba€raph and the LCD display. Once we are done with

writing to the l-CD we can load the data into POR'ID and pause the pogmm to allow us lo

read the display. Notice that the pause/delay must come immediately after setting PORTD to

A2D Value for this to work properly. when we do wha!, is important when using micrccon-

trollers. Program 5.6 shows us how this is done and Figure 5.4 shows the rclevant cinruiiry.

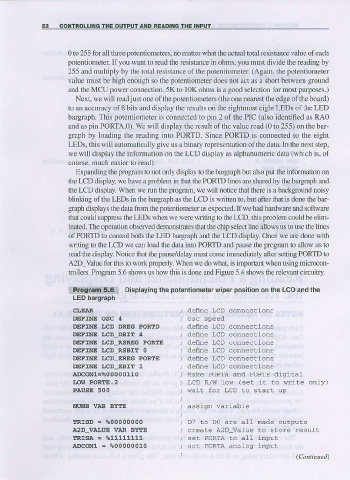

l:lpiiltriiiiilEii Disprayins thepotentiometer wiper position on the LCD and the

LED bargraph

CI,EAR ; def,ne LCD connections

DEFINE OgC 4

DEFINE I.cD DREG PORTD ; deflne LcD connections

DEFINE I,CD_DBIT 4 , denne LcD connections

DEFINE I,CD_RSREG PORTE ; deine LCD connections

DEFINE I.CD RSBTE O ; deine LcD connections

DEAINE I.CD EREG PORTE ; def,ne LcD connections

DEFINE I.CD EBIT 1 ; def,ne LcD connections

A.DCONI=?0 0000110 ; Make PORTA and PORTE digila1

IJOW PORTE.2 ; LCD R/W low (set it to write only)

PAUSE 5OO ; wait for LcD to start up

NUIIB VAR BYTE

IRtsD = %00000000

A2D VAI.UE VAR BYTE to store resuLt

IRISA = %11111111

A.DcONl = %00000010 ; se! poRTA analog