Page 261 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 261

Liquid

L

" ‘D 4/Q l/

T _

Q lLj_S_f°'oS___ ' S " ____

0

5 Q ' ' _

g Solid Q.

S

P %

+

L

\ Solid l<- Liquid

-»|

Pure metal Alloying element (%) l\/lushy zone

Dendrites

-'i m

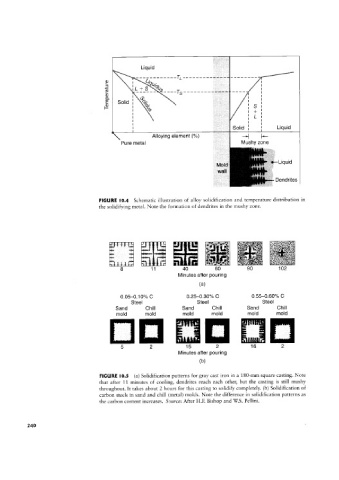

FIGURE I0.4 Schematic illustration of alloy solidification and temperature distribution in

the solidifying metal. Note the formation of dendrites in the mushy zone.

f’°”T‘**`¥*7§!>"”". 2%

' J

' »<e1 ;

"i§?¥%?\?§:'ef

8 11 40 60 90 102

Minutes after pouring

(H)

0.05-0.10% C 0.25-0.30% C 0.55-0.60% C

Steel Steel Steel

Sand Chill Sand Chill Sand Chill

mold mold mold mold mold mold

Q ' il il "H

-Tl ~ an

5 2 15 2 1 6 2

Minutes after pouring

(bl

FIGURE l0.5 (a) Solidification patterns for gray cast iron in a 180-mm square casting. Note

that after ll minutes of cooling, dendrites reach each other, but the casting is still mushy

throughout. It takes about 2 hours for this casting to solidify completely. (bl Solidification of

carbon steels in sand and chill (metal) molds. Note the difference in solidification patterns as

the carbon content increases. Source: After H.F. Bishop and WS. Pellini.

2