Page 257 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 257

23 Part II Metal-Casting Processes and Equipment

Engine block,

Alternator PISYOU

housing

Grill

Water pump,

pulleys Differential

Intake and l1°US'"9

exhaust

manifolds

Wheels,

disk brakes Brake

Transmission Door Cynnders

housing handles LOCKS

Brake rotors

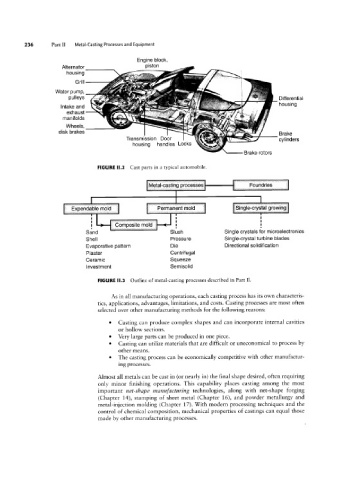

FIGURE II.2 Cast parts in a typical automobile.

Met l-casting processes

Expandable mold Permanent (mold l ingl e-crystal grow ng

I

' : :

Composite mold

5 5 5

Sand if i 4' Slush Single crystals for microelectronics

Shell Pressure Single-crystal turbine blades

Evaporative pattern Die Directional solidification

Plaster Centrifugal

Ceramic Squeeze

investment Semisolid

FIGURE II.3 Outline of metal-casting processes described in Part II.

As in all manufacturing operations, each casting process has its own characteris-

tics, applications, advantages, limitations, and costs. Casting processes are most often

selected over other manufacturing methods for the following reasons:

' Casting can produce complex shapes and can incorporate internal cavities

or hollow sections.

° Very large parts can be produced in one piece.

° Casting can utilize materials that are difficult or uneconomical to process by

other means.

° The casting process can be economically competitive with other manufactur-

ing processes.

Almost all metals can be cast in (or nearly in) the final shape desired, often requiring

only minor finishing operations. This capability places casting among the most

important net-shape manufacturing technologies, along with net-shape forging

(Chapter 14), stamping of sheet metal (Chapter 16), and powder metallurgy and

metal-injection molding (Chapter 17). With modern processing techniques and the

control of chemical composition, mechanical properties of castings can equal those

made by other manufacturing processes.