Page 300 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 300

Section 11.4 Permanent-mold Castrng Processes 2

graphite or metal mold. The pressure is maintained until the metal has solidified

completely in the mold. The molten metal also may be forced upward by a vacuum,

which also removes dissolved gases and produces a casting with lower porosity.

Pressure casting generally is used for high-quality castings, such as steel railroad-car

wheels, although these wheels also may be cast in sand molds or semipermanent

molds made of graphite and sand.

I I.4.5 Die Casting

The die-casting process, developed in the early 1900s, is a further example of

permanent-mold casting. The European term for this process is pressure die casting

and should not be confused with pressure casting described in Section 11.4.4.

Typical parts made by die casting are housings, business-machine and appliance

components, hand-tool components, and toys. The weight of most castings ranges

from less than 90 g to about 25 kg. Equipment costs, particularly the cost of dies,

are somewhat high, but labor costs are generally low, because the process is semi- or

fully automated. Die casting is economical for large production runs. The capabili-

ties of die casting are given in Table 11.2.

In the die-casting process, molten metal is forced into the die cavity at pres-

sures ranging from 0.7 to 700 MPa. There are two basic types of die-casting ma-

chines: hot-chamber and cold-chamber machines.

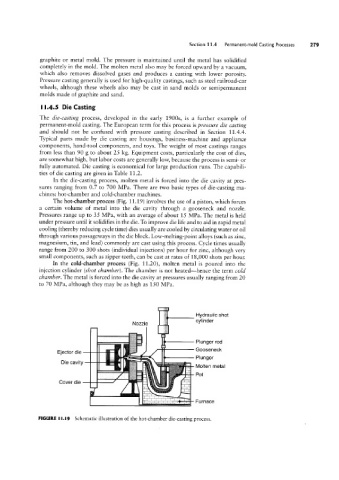

The hot-chamber process (Fig. 1 1.19) involves the use of a piston, which forces

a certain volume of metal into the die cavity through a gooseneck and nozzle.

Pressures range up to 35 MPa, with an average of about 15 MPa. The metal is held

under pressure until it solidifies in the die. To improve die life and to aid in rapid metal

cooling (thereby reducing cycle time) dies usually are cooled by circulating water or oil

through various passageways in the die block. Low-melting-point alloys (such as zinc,

magnesium, tin, and lead) commonly are cast using this process. Cycle times usually

range from 200 to 300 shots (individual injections) per hour for zinc, although very

small components, such as zipper teeth, can be cast at rates of 18,000 shots per hour.

In the cold-chamber process (Fig. 1120), molten metal is poured into the

injection cylinder (shot chamber). The chamber is not heated-hence the term cold

chamber. The metal is forced into the die cavity at pressures usually ranging from 20

to 70 MPa, although they may be as high as 150 MPa.

Hydraulic shot

Nozzle cylinder

1- Plunger rod

li Gooseneck

Ejector die

Plunger

D'e Cav” Molten metal

Pot

Cover die

Furnace

FIGURE |.I9 Schematic illustration of the hot-chamber die-casting process.

I