Page 302 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 302

Section 11.4 Permanent-mold Casting Processes 28l

TABLE l l.3

Properties and Typical Applications of Same (Zommon Die-casting Alloys

Ultimate

tensile Yield Elongation

strength strength in 50 mm

Alloy (MPa) (MPa) (%) Applications

Aluminum 380 (3.5 Cu-8.5 Si) 320 2.5 Appliances, automotive components,

electrical motor frames and housings

13 (12 Si) 300 2.5 Complex shapes with thin walls, parts

requiring strength at elevated

temperatures

Brass 858 (60 Cu) 380 15 Plumbing fixtures, lock hardware,

bushings, ornamental castings

Magnesium AZ91 B (9 Al-0.7 Zn) 230 3 Power tools, automotive parts,

sporting goods

Zinc No. 3 (4 Al) 280 10 Automotive parts, office equipment,

household utensils, building

hardware, toys

No. 5 (4 Al-1 Cu) 320 7 Appliances, automotive parts,

building hardware, business

equipment

Source: American Die Casting Institute.

wall thickness. With a good surface finish and dimensional accuracy, die casting can

produce smooth surfaces for bearings that otherwise normally would be machined.

Components such as pins, shafts, and threaded fasteners can be die cast inte-

grally. Called insert molding, this process is similar to placing wooden sticks in pop-

sicles prior to freezing (see also Section 19.3). For good interfacial strength, insert

surfaces may be knurled (see Fig. 23.11 on page 616), grooved, or splined. Steel,

brass, and bronze inserts are used commonly in die-casting alloys. In selecting insert

materials, the possibility of galvanic corrosion should be taken into account. To

avoid this potential problem, the insert can be insulated, plated, or surface treated.

Because of the high pressures involved, dies for die casting have a tendency to

part unless clamped together tightly. Die-casting machines are thus rated according

to the clamping force that can be exerted to keep the dies closed. The capacities of

$1

commercially available machines range from about 23 to 2700 metric tons. Other

factors involved in the selection of die-casting machines are die size, piston stroke,

shot pressure, and cost.

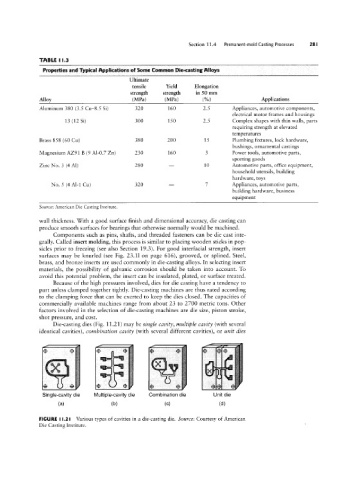

Die-casting dies (Fig. 11.21) may be single cat/ity, multiple cat/ity (with several

identical cavities), combination cavity (with several different cavities), or unit dies

,,_,

@ ii 5 iii

,,

Q’

Single-cavity die Multiple-cavity die Combination die Unit die

(H) (D) (C) (d)

FIGURE ll.2I Various types of cavities in a die-casting die. Source: Courtesy of American

Die Casting Institute.