Page 301 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 301

280 Chapter 11 Metal-Casting Processes and Equipment

Cavity Stationary platen

Electignpcgiri Ladle Hydraulic

C |'nder

Y'

iri

Ejector or _

®

.,rtra Stationary Shot Plunger

I

die half

1

m_ .ll |?|

,,_,,,_ _,_

,,;;, ;_:

Ejector box

il

sleeve rod

die half

M "““'““

,_

,

plunger

rr r r_tt

P'U'"'Qef VOC*

T i. Pouring hole

fu.

t.: Av. x

. ,

_,,_,

Closing Clamp Ejector Cover Metal Shot

cylinder mechanism box disc sleeve cylinder

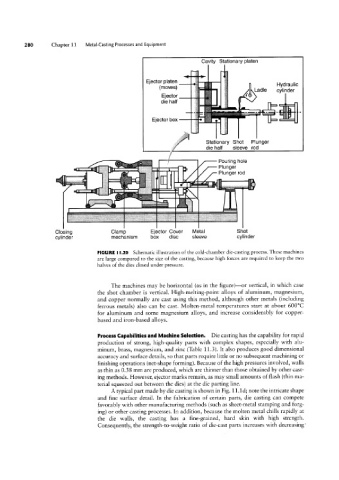

FIGURE I I.20 Schematic illustration of the cold-chamber die-casting process. These machines

are large compared to the size of the casting, because high forces are required to keep the two

halves of the dies closed under pressure.

The machines may be horizontal (as in the figure)-or vertical, in which case

the shot chamber is vertical. High-melting-point alloys of aluminum, magnesium,

and copper normally are cast using this method, although other metals (including

ferrous metals) also can be cast. Molten-metal temperatures start at about 600°C

for aluminum and some magnesium alloys, and increase considerably for copper-

based and iron-based alloys.

Process Capabilities and Machine Selection. Die casting has the capability for rapid

production of strong, high-quality parts with complex shapes, especially with alu-

minum, brass, magnesium, and zinc (Table 11.3). It also produces good dimensional

accuracy and surface details, so that parts require little or no subsequent machining or

finishing operations (net-shape forming). Because of the high pressures involved, walls

as thin as 0.38 mm are produced, which are thinner than those obtained by other cast-

ing methods. However, ejector marks remain, as may small amounts of flash (thin ma-

terial squeezed out between the dies) at the die parting line.

A typical part made by die casting is shown in Fig. 1 1.1d; note the intricate shape

and fine surface detail. In the fabrication of certain parts, die casting can compete

favorably with other manufacturing methods (such as sheet-metal stamping and forg-

ing) or other casting processes. In addition, because the molten metal chills rapidly at

the die walls, the casting has a fine-grained, hard skin with high strength.

Consequently, the strength-to-weight ratio of die-cast parts increases with decreasing