Page 322 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 322

Section 12.2 Design Considerations in Casting 30|

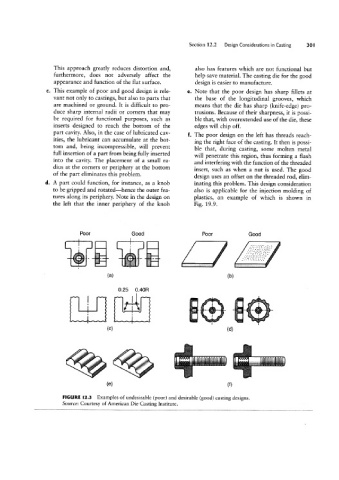

This approach greatly reduces distortion and, also has features which are not functional but

furthermore, does not adversely affect the help save material. The casting die for the good

appearance and function of the flat surface. design is easier to manufacture.

This example of poor and good design is rele- Note that the poor design has sharp fillets at

vant not only to castings, but also to parts that the base of the longitudinal grooves, which

are machined or ground. It is difficult to pro- means that the die has sharp (knife-edge) pro-

duce sharp internal radii or corners that may trusions. Because of their sharpness, it is possi-

be required for functional purposes, such as ble that, with overextended use of the die, these

inserts designed to reach the bottom of the edges will chip off.

part cavity. Also, in the case of lubricated cav-

The poor design on the left has threads reach-

ities, the lubricant can accumulate at the bot-

ing the right face of the casting. It then is possi-

tom and, being incompressible, will prevent

ble that, during casting, some molten metal

full insertion of a part from being fully inserted

Will penetrate this region, thus forming a flash

into the cavity. The placement of a small ra-

and interfering with the function of the threaded

dius at the corners or periphery at the bottom

insert, such as when a nut is used. The good

of the part eliminates this problem.

design uses an offset on the threaded rod, elim-

A part could function, for instance, as a knob inating this problem. This design consideration

to be gripped and rotated-hence the outer fea- also is applicable for the injection molding of

tures along its periphery. Note in the design on plastics, an example of which is shown in

the left that the inner periphery of the knob Fig. 19.9.

Poor Good Poor Good

i Q .__.,_

(H) (D) , .

0.25 0.4OFi

. ....,. .....

| .

. I 5

".:

_v_____|>____v_ _____v_|`______ V,,_,

(C) (d)

(9) (f)

FIGURE l2.3 Examples of undesirable (poor) and desirable (good) casting designs.

Source: Courtesy of American Die Casting Institute.