Page 152 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 152

gi; - Section 5.2 Production of Iron and Steel

..f’,i

il!

¢,;fEgi;,§:

Blast furnace

Pellets

Iron ore Gas uptakes

...K

‘ 5” '°”

ni

* f i *

ff”

Coal

g

'*"'l __ \ coke and limestone

Slnlel

Layers of iron ore

rus e Refractory ‘f*‘§ii» f“1f;a»; El

wéazst ifirr

=_ »e **

Us ala-

.\lr i

fy i: i

Limestone . h d Stee| She" \ .im fe- r

-

1

.1

r

H

1-»-»-j

-~

la.-mill?

"""‘9

BUSUG Pipe __l.

§l§l;§f»””f

tstaiaili -»-

,, ,,,

1;‘3*;ff- le* _)v in »rw!ii~i¢ls??s"1=»; we re” =. "' “':!"" Hot b|aSt a|f'

‘ »'~~ , Qiariiaéég Slag Molten iron

Coke ovens

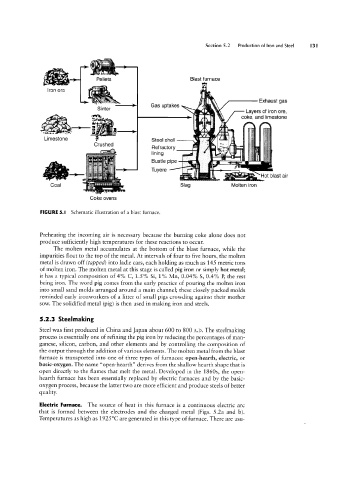

FIGURE 5.l Schematic illustration of a blast furnace.

Preheating the incoming air is necessary because the burning coke alone does not

produce sufficiently high temperatures for these reactions to occur.

The molten metal accumulates at the bottom of the blast furnace, while the

impurities float to the top of the metal. At intervals of four to five hours, the molten

metal is drawn off (rapped) into ladle cars, each holding as much as 145 metric tons

of molten iron. The molten metal at this stage is called pig iron or simply hot metal;

it has a typical composition of 4% C, 1.5% Si, 1% Mn, 0.04% S, 0.4% P, the rest

being iron. The word pig comes from the early practice of pouring the molten iron

into small sand molds arranged around a main channel; these closely packed molds

reminded early ironworkers of a litter of small pigs crowding against their mother

sow. The solidified metal (pig) is then used in making iron and steels.

5.2.3 Steelmaking

Steel was first produced in China and Japan about 600 to 800 A.D. The steelmaking

process is essentially one of refining the pig iron by reducing the percentages of man-

ganese, silicon, carbon, and other elements and by controlling the composition of

the output through the addition of various elements. The molten metal from the blast

furnace is transported into one of three types of furnaces: open-hearth, electric, or

basic-oxygen. The name “open-hearth” derives from the shallow hearth shape that is

open directly to the flames that melt the metal. Developed in the 1860s, the open-

hearth furnace has been essentially replaced by electric furnaces and by the basic-

oxygen process, because the latter two are more efficient and produce steels of better

quality.

Electric Furnace. The source of heat in this furnace is a continuous electric arc

that is formed between the electrodes and the charged metal (Figs. 5.2a and b).

Temperatures as high as 1925°C are generated in this type of furnace. There are usu-