Page 156 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 156

Section 5.4 Continuous Casting

Electric furnace

l Tumdish

Platform; 20 m

above ground level

Cooling water Argon

X ray receiver //’ » .

Xqay (Controls pouring rate)

Molten metal

Solidified metal

Air gap Top belt (carbon steel)

TUf1diSh High-velocity

Catch basin Backup rolls cooling waterjets

r

Pinch rolls -_ T GFISIOVI

P“"eY

W” '° ~° ~= - e 3

Nip pulley

Synchronized

`ncn Il

Water nozzle pI ro S

Bottom

Starting dummy OXVQGU |3009 Edge dam blocks belt Water gutters

(for cutting)

(H) (D)

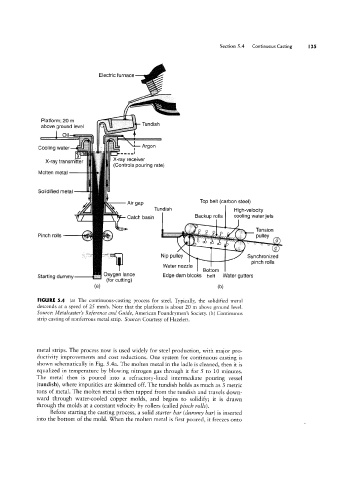

FIGURE 5.4 (a) The continuous-casting process for steel. Typically, the solidified metal

descends at a speed of 25 mm/s. Note that the platform is about 20 m above ground level.

Source: Metalcasterls Reference and Guide, American Foundrymen’s Society. (b) Continuous

strip casting of nonferrous metal strip. Source: Courtesy of Hazelett.

metal strips. The process novv is used widely for steel production, with major pro-

ductivity improvements and cost reductions. One system for continuous casting is

shown schematically in Pig. 5 .4a. The molten metal in the ladle is cleaned, then it is

equalized in temperature by blowing nitrogen gas through it for 5 to 10 minutes.

The metal then is poured into a refractory-lined intermediate pouring vessel

(tundish), where impurities are skimmed off. The tundish holds as much as 3 metric

tons of metal. The molten metal is then tapped from the tundish and travels down-

ward through vvater-cooled copper molds, and begins to solidify; it is drawn

through the molds at a constant velocity by rollers (called pinch rolls).

Before starting the casting process, a solid starter bar (dummy bar) is inserted

into the bottom of the mold. When the molten metal is first poured, it freezes onto