Page 153 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 153

so

Chapter 5 Ferrous Metals and Alloys: Production, General Properties, and Applications

QQ; I ' ‘QS Door 3-11% Co er

Carbon electrodes Molten

poweneads

Elect odes

metal

e I

A ‘l

lr

cement

l ‘mm bg

:

Cons

;

5

,` ______;€ Trunnlon gr Flefracwrv 'Fi indligrion

Crucible

:

\§ § _%;f/ Roller g

,L

,Ei

Rammed T Q I I

hearth Metal Slag

(H) (D) (C)

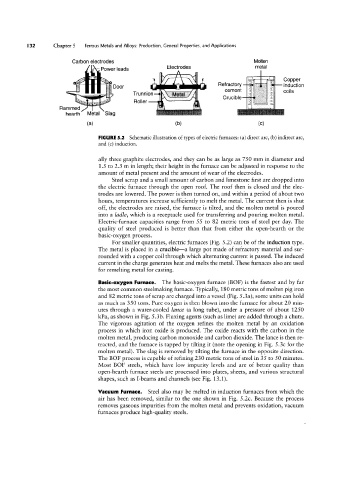

FIGURE 5.2 Schematic illustration of types of electric furnaces: (a) direct arc, (b) indirect arc,

and (c) induction.

ally three graphite electrodes, and they can be as large as 750 mm in diameter and

1.5 to 2.5 m in length; their height in the furnace can be adjusted in response to the

amount of metal present and the amount of wear of the electrodes.

Steel scrap and a small amount of carbon and limestone first are dropped into

the electric furnace through the open roof. The roof then is closed and the elec-

trodes are lowered. The power is then turned on, and within a period of about two

hours, temperatures increase sufficiently to melt the metal. The current then is shut

off, the electrodes are raised, the furnace is tilted, and the molten metal is poured

into a ladle, which is a receptacle used for transferring and pouring molten metal.

Electric-furnace capacities range from 55 to 82 metric tons of steel per day. The

quality of steel produced is better than that from either the open-hearth or the

basic-oxygen process.

For smaller quantities, electric furnaces (Fig. 5.2) can be of the induction type.

The metal is placed in a Crucible-a large pot made of refractory material and sur-

rounded with a copper coil through which alternating current is passed. The induced

current in the charge generates heat and melts the metal. These furnaces also are used

for remelting metal for casting.

Basic-oxygen Furnace. The basic-oxygen furnace (BOF) is the fastest and by far

the most common steelmaking furnace. Typically, 180 metric tons of molten pig iron

and 82 metric tons of scrap are charged into a vessel (Fig. 5 .3a); some units can hold

as much as 350 tons. Pure oxygen is then blown into the furnace for about 20 min-

utes through a water-cooled lance (a long tube), under a pressure of about 1250

kPa, as shown in Fig. 5 .3b. Fluxing agents (such as lime) are added through a chute.

The vigorous agitation of the oxygen refines the molten metal by an oxidation

process in which iron oxide is produced. The oxide reacts with the carbon in the

molten metal, producing carbon monoxide and carbon dioxide. The lance is then re-

tracted, and the furnace is tapped by tilting it (note the opening in Fig. 5 .3c for the

molten metal). The slag is removed by tilting the furnace in the opposite direction.

The BOF process is capable of refining 230 metric tons of steel in 35 to 50 minutes.

Most BOF steels, which have low impurity levels and are of better quality than

open-hearth furnace steels are processed into plates, sheets, and various structural

shapes, such as I-beams and channels (see Fig. 13.1).

Vacuum Furnace. Steel also may be melted in induction furnaces from which the

air has been removed, similar to the one shown in Fig. 5.2c. Because the process

removes gaseous impurities from the molten metal and prevents oxidation, vacuum

furnaces produce high-quality steels.