Page 489 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 489

Section 18.2 Shaping Ceramics 46

Air (filtered)

Exhaust

in

out

Ceramic tape

on carrierta e - I - Slurry chamber and

1: ....' doctor blade [Ceramic slurry

p

Ir

Drying

Supply lube

will HQ

i ii

,.'I"~;"*

"`

Take-up 5

§"'

er .....

spool 3* Carrier film

§

Controller

for take-up

SpOO|

Doctor blade

Ceramic film 2%

l

Carrierfilm

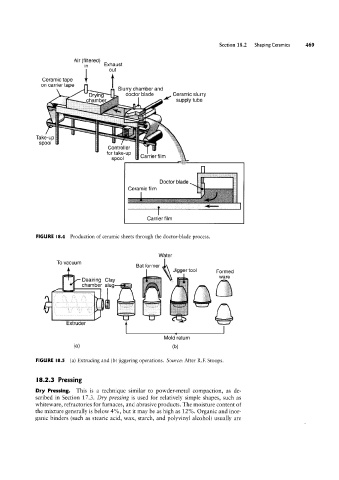

FIGURE |8.4 Production of ceramic sheets through the doctor-blade process.

l,...l,l,ll,,le ,lrre g‘» - Formed

l i

Water

chamber slug

Bat former

To Vacuum

JIQQGV tool

',,}

§ as `

1 _ v

Deal |'lHQ Clay

W re

"¢=,

Y

i

_

“i#lw~mevlv¢*4'

Extruder

1 l

l\/Iold return

(3) (b)

FIGURE |8.5 (a) Extruding and (b) jiggering operations. Source: After R.F. Stoops.

l8.2.3 Pressing

Dry Pressing. This is a technique similar to powder-metal compaction, as de-

scribed in Section 17.3. Dry pressing is used for relatively simple shapes, such as

Whitevvare, refractories for furnaces, and abrasive products. The moisture content of

the mixture generally is below 4%, but it may be as high as 12%. Organic and inor-

g anic bind ers (suc h as stearic acid, Wax, starch, and polyvinyl alcohol) usually are