Page 493 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 493

Section 18.3 Forming and Shaping of Glass 473

an old-fashioned clothes wringer. The solidifying glass

Glass products generally can be categorized as follows:

I. Flat sheets or plates ranging in thickness from about 0.8 to 10 mm, such as

window glass, glass doors, and tabletops.

2. Rods and tubing used for chemicals, neon lights, and decorative artifacts.

3. Discrete products such as bottles, vases, headlights, and television tubes.

4. Glass fibers to reinforce composite materials (Section 9.2.1) and for use in

fiber optics.

All glass forming and shaping processes begin with molten glass, typically in

the range from 1000° to 1200°C. The glass has the appearance of a red-hot, viscous

syrup and is supplied from a melting furnace or tank.

l8.3.l Flat-sheet and Plate Glass

Flat-sheet glass can be made by the float glass method or by drawing or rolling it

from the molten state (all three methods are continuous processes):

l. In the float method (Fig. 18.7), molten glass from the furnace is fed into a long

bath in which the glass-under a controlled atmosphere and at a temperature

of 115O°C-floats over a bath of molten tin. The glass then moves at a temper-

ature of about 65 0°C over rollers into another chamber (le/ar), where it solidi-

fies. Float glass has smooth (/Qre-polished) surfaces, so further grinding or

polishing is not necessary. The width can be as much as 4 m. Both thin and

between powered rollers, thereby forming a sheet. The sur- Controlled Furnace

plate glass are made by this process.

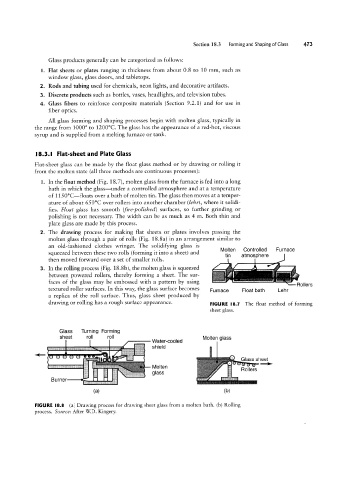

2. The drawing process for making flat sheets or plates involves passing the

molten glass through a pair of rolls (Fig. 18.8a) in an arrangement similar to

is

Molten

squeezed between these two rolls (forming it into a sheet) and

gg

h

1'

atmosp ere

then moved forward over a set of smaller rolls.

3. In the rolling process (Fig. 18.8b), the molten glass is squeezed In ~°*‘~‘~~~~~~~'~~~'~»~~~~~‘~~~'»»»»»»»»r--»»»-»»»»

,

faces of the glass may be embossed with a pattern by using * °"rr”°'° 539' Rollers

textured roller surfaces. In this way, the glass surface becomes Furnace Float bath Lehr

a replica of the roll surface. Thus, glass sheet produced by

drawing or rolling has a rough surface appearance. FIGURE |8.1 The float method of forming

sheet glass.

Water-cooled M O en gass

Turning Forming

Glass

sheet

roll

roll

|t

if § “"°"e" Rollers Sheet

(_ rrrrr § Shield

° ° ° ° ° *Wi

_

Bum-°

9'aSS

(H) (D)

FIGURE |8.8 (a) Drawing process for drawing sheet glass from a molten bath. (b) Rolling

process. Source: After WD. Kingery.