Page 496 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 496

' ,_::f;f; t hermoforming of thermoplastics (Section 19.6), but no pressure or

476 Ceramics, Glasses, and Superconductors: Processing and Equipment

Chapter 18

z vacuum is involved. Typical applications are dishes, sunglass lenses,

_‘;x:;§1

mirrors for telescopes, and lighting panels.

Glass ceramics (trade names: Pyroceram,

Glass Ceramics Manufacture.

Mold (Steel)

Corningu/are) contain large proportions of several oxides, as noted in

Section 8.5. thus, their manufacture involves a combination of the

methods used for ceramics and glasses. Glass ceramics are shaped into

1__.» discrete products (such as dishes and baking pans) and then heat treated,

whereby glass becomes dei/itri/‘ted (recrystallized).

FIGURE l8.l3 Centrifugal casting of glass. l8.3.4 Glass Fibers

Large telescope lenses and television-tube

funnels are made by this process. Source: Continuous glass fibers are drawn through multiple orifices (200 to

Courtesy of Corning Glass Works. 400 holes) in heated platinum plates at speeds as high as 500 m/s.

Fibers as small as 2 /.tm in diameter can be produced by this method. In

order to protect their surfaces, fibers subsequently are coated with chemicals. Short

fibers (chopped) are produced by subjecting long fibers to compressed air or steam

as they leave the orifice.

Glass wool (short glass fibers)-used as a thermal insulating material or for

acoustic insulation-is made by a centrifugal spraying process in which molten glass

is ejected (spun) from a rotating head. The diameter of the fibers is typically in the

range from 20 to 30 /sum.

l8.4 Techniques for Strengthening and Annealing Glass

Glass can be strengthened by a number of processes, and discrete glass products

may be subjected to annealing and to other finishing operations to impart desired

properties and surface characteristics.

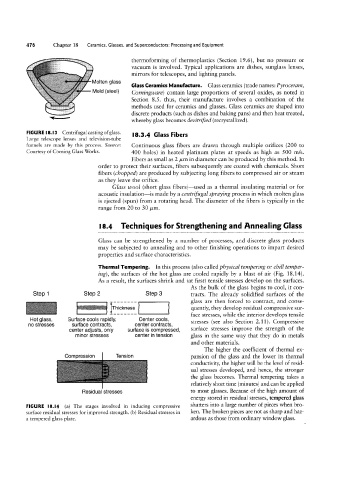

'!'hermal Tempering. In this process (also called physical tempering or c/oil] temper-

ing), the surfaces of the hot glass are cooled rapidly by a blast of air (Fig. 18.14).

As a result, the surfaces shrink and (at first) tensile stresses develop on the surfaces.

As the bulk of the glass begins to cool, it con-

STQP1 Step 2 Step 3 tracts. The already solidified surfaces of the

------- glass are then forced to contract, and conse-

Thickness quently, they develop residual compressive sur-

iiiiii ii' glass in the same Way that they do in metals

T ' ef

‘i`= "i‘:‘ Surface CODIS rapiduz""“' Center Coots face stresses, while the _interior develops tensile

surface contracts,

no stresseis Centeradjusts, 0n|y Surfaceis Compressed’ stresses (See alSO_ Secuon 2'11)` Compress”/6

centercontracls,

surface stresses improve the strength of the

center in tension

minor SIVGSSGS

and other materials.

The higher the coefficient of thermal ex-

pansion of the glass and the lower its thermal

Compression

Tension

conductivity, the higher will be the level of resid-

W i&FNT

the glass becomes. Thermal tempering takes a

ggir

relatively short time (minutes) and can be applied

to most glasses. Because of the high amount of

Residual stresses ual stresses developed, and hence, the stronger

energy stored in residual stresses, tempered glass

FIGURE l8.l4 (a) The stages involved in inducing compressive shatters into a large number of pieces when bro-

surface residual stresses for improved strength. (b) Residual stresses in ken. The broken pieces are not as sharp and haz-

a tempered glass plate. ardous as those from ordinary window glass.