Page 495 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 495

Gob Blow

head

4- Air i Baffle

ff.;

1

I-mg 1 mx EAI "li"

1

:Ax

""?°K T|p

Air

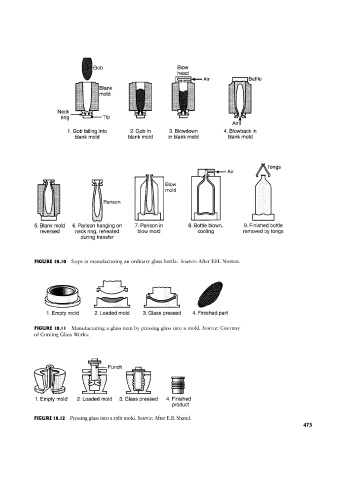

1. Gob falling into 2. Gob in 3. Blowdown 4. Blowback in

blank mold blank mold in blank mold blank mold

Tongs

l 4- Air

~ ..- ~ Blow

J " mold

Parison

¥< ” "

5. Blank mold 6. Parison hanging on 7. Parison in 8. Bottle blown, 9. Finished bottle

reversed neck ring, reheated blow mold cooling removed by tongs

during transfer

I

FIGURE I8.l0 Steps in manufacturing an ordinary glass bottle. Source: After F.H. Norton.

V-*L

1. Empty mold 2. Loaded mold 3. Glass pressed 4. Finished part

FIGURE l8.l I Manufacturing a glass item by pressing glass into a mold. Source: Courtesy

of Corning Glass Works.

é

' Punch _,E

U

§ `fi` ` ml

1. Empty mold 2. Loaded mold 3. Glass pressed 4. Finished

product

FIGURE l8.l2 Pressing glass into a split mold. Source: After E.B. Shand.