Page 613 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 613

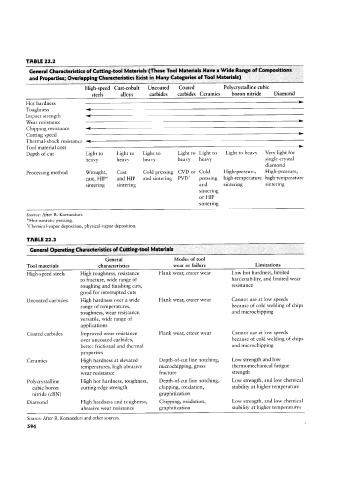

TABLE 22.2

General Characteristics of Cutting-tool Materials (These Tool Materials Have a Wide Range nf Compositions

and Properties; Overlapping Characteristics Exist in Many Categories of Tool Materials)

High-speed Cast-cobalt Uncoated Coated Polycrystalline cubic

steels alloys carbides carbides Ceramics boron nitride Diamond

>

Hot hardness

Toughness 4

Impact strength 4

Wear resistance >

Chipping resistance 4

Cutting speed >

Thermal-shock resistance 4

Tool material cost >

Depth of cut Light to Light to Light to Light to Light to Light to heavy Very light for

heavy heavy heavy heavy heavy single-crystal

diamond

Processing method Wrought, Cast Cold pressing CVD or Cold High-pressure, High-pressure,

cast, HIP* and HIP and sintering PVDI pressing high-temperature high-temperature

sintering sintering and sintering sintering

sintering

or HIP

sintering

Source: After R. Komanduri.

"Hot~isostatic pressing.

lChemical-vapor deposition, physical-vapor deposition.

TABLE 22.3

General Operating Characteristics of Cutting-tool Materials

General Modes of tool

Tool materials characteristics wear or failure Limitations

High-speed steels High toughness, resistance Flank Wear, crater wear Low hot hardness, limited

to fracture, wide range of hardenability, and limited wear

roughing and finishing cuts, resistance

good for interrupted cuts

Uncoated carbides High hardness over a wide Flank Wear, crater Wear Cannot use at low speeds

range of temperatures, because of cold Welding of chips

toughness, Wear resistance, and microchipping

versatile, wide range of

applications

Coated carbides Improved Wear resistance Flank Wear, crater Wear Cannot use at low speeds

over uncoated carbides, because of cold Welding of chips

better frictional and thermal and microchipping

properties

Ceramics High hardness at elevated Depth-of-cut line notching, Low strength and low

temperatures, high abrasive microchipping, gross thermomechanical fatigue

Wear resistance fracture strength

Polycrystalline High hot hardness, toughness, Depth-of-cut line notching, Low strength, and low chemical

cubic boron cutting-edge strength chipping, oxidation, stability at higher temperature

nitride (CBN) graphitization

Diamond High hardness and toughness, Chipping, oxidation, Low strength, and low chemical

abrasive wear resistance graphitization stability at higher temperatures

Source: After R. Komanduri and other sources.

594