Page 617 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 617

598 Chapter 22 Cutting-Tool Materials and Cutting Fluids

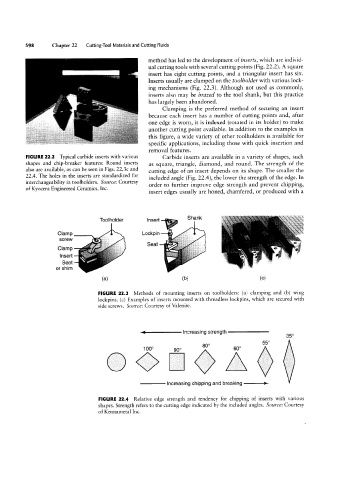

method has led to the development of inserts, which are individ-

ual cutting tools With several cutting points (Fig. 22.2). A square

insert has eight cutting points, and a triangular insert has six.

Inserts usually are clamped on the tool/colder with various lock-

ing mechanisms (Fig. 22.3). Although not used as commonly,

inserts also may be brazed to the tool shank, but this practice

has largely been abandoned.

Clamping is the preferred method of securing an insert

because each insert has a number of cutting points and, after

one edge is worn, it is indexed (rotated in its holder) to make

another cutting point available. ln addition to the examples in

this figure, a Wide variety of other toolholders is available for

specific applications, including those with quick insertion and

removal features.

FIGURE 22.2 Typical carbide inserts with various Carbide inserts are available in a variety of shapes, such

shapes and chip-breaker features: Round inserts as square, triangle, diamond, and round. The strength of the

also are available, as can be seen in Figs. 22.3c and cutting edge of an insert depends on its shape. The smaller the

22.4. The holes in the inserts are standardized for included angle (Fig. 22.4), the lower the strength of the edge. In

interchangeability in toolholders. Source: Courtesy order to further improve edge strength and prevent chipping,

of Kyocera Engineered Ceramics, Inc.

insert edges usually are honed, chamfered, or produced with a

Shank

Toolholder Insert .

Clamp Lockpin

screw

Seat

Clamp

Insert a:»=.§4“

Seat

or shim

(H) (D) (C)

FIGURE 22.3 Methods of mounting inserts on toolholders: (a) clamping and (b) wing

lockpins. (c) Examples of inserts mounted with threadless lockpins, which are secured with

side screws. Source: Courtesy of Valenite.

th---1

ncreaslng t s reng 350

0 55° S

100° 90° Bio 60° 3

Increasing chipping and breaking L-->

FIGURE 22.4 Relative edge strength and tendency for chipping of inserts with various

shapes. Strength refers to the cutting edge indicated by the included angles. Source: Courtesy

of Kennametal Inc.