Page 620 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 620

Section 22 5 Coated Tools

100 Carbon steel

E 26 High-speed steel

§- 15 Cast cobalt-based alloys

_§

ga 6 Cemented carbides

FE 3 Improved carbide grades

O

$5 1_5 First coated grades

1 First double-coated grades

0_7 First triple-coated grades

0.5 Functionally graded triple coated

1900 1910 1920 1930 1940 1950 1960 1970 1980 1990 2000

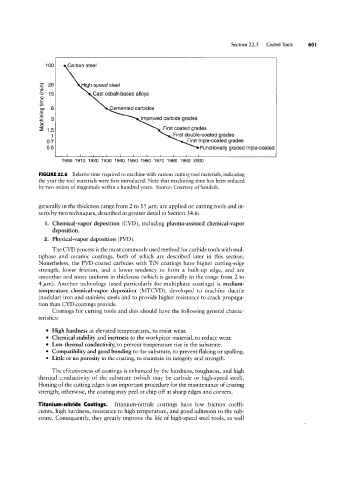

FIGURE 22.6 Relative time required to machine with various cutting-tool materials, indicating

the year the tool materials were first introduced. Note that machining time has been reduced

by two orders of magnitude within a hundred years. Source: Courtesy of Sandvik.

generally in the thickness range from 2 to 15 um, are applied on cutting tools and in-

serts by two techniques, described in greater detail in Section 34.6:

I. Chemical-vapor deposition (CVD), including plasma-assisted chemical-vapor

deposition.

2. Physical-vapor deposition (PVD).

The CVD process is the most commonly used method for carbide tools with mul-

tiphase and ceramic coatings, both of which are described later in this section.

Nonetheless, the PVD-coated carbides with TiN coatings have higher cutting-edge

strength, lower friction, and a lower tendency to form a built-up edge, and are

smoother and more uniform in thickness (which is generally in the range from 2 to

4 um). Another technology (used particularly for multiphase coatings) is medium-

temperature chemical-vapor deposition (MTCVD), developed to machine ductile

(nodular) iron and stainless steels and to provide higher resistance to crack propaga-

tion than CVD coatings provide.

Coatings for cutting tools and dies should have the following general charac-

teristicsz

° High hardness at elevated temperatures, to resist wear.

° Chemical stability and inertness to the workpiece material, to reduce wear.

° Low thermal conductivity, to prevent temperature rise in the substrate.

° Compatibility and good bonding to the substrate, to prevent flaking or spalling.

° Little or no porosity in the coating, to maintain its integrity and strength.

The effectiveness of coatings is enhanced by the hardness, toughness, and high

thermal conductivity of the substrate (which may be carbide or high-speed steel).

Honing of the cutting edges is an important procedure for the maintenance of coating

strength; otherwise, the coating may peel or chip off at sharp edges and corners.

Titanium-nitride Coatings. Titanium-nitride coatings have low friction coeffi-

cients, high hardness, resistance to high temperature, and good adhesion to the sub-

strate. Consequently, they greatly improve the life of high-speed steel tools, as well