Page 72 - 04. Subyek Engineering Materials - Manufacturing, Engineering and Technology SI 6th Edition - Serope Kalpakjian, Stephen Schmid (2009)

P. 72

Section 1.7 Recovery, Recrystallization, and Grain Growth 5|

the direction of the tensile force. By contrast, slip planes under compression tend

to align themselves in a direction perpendicular to the direction of the compressive

force.

Mechanical Fibering. This is a type of anistropy that results from the alignment of

inclusions (stringers), impurities, and voids in the metal during deformation. Note

that if the spherical grains in Fig. 1.11a were coated with impurities, these impurities

would align themselves in a generally horizontal direction after deformation.

Because impurities weaken the grain boundaries, this piece of metal will now be

weaker and less ductile when tested in the vertical direction. As an analogy, consider

lowers the strength, and raises the ductility of the

plywood, which is strong in tension along its planar direction, but peels off (splits)

easily when pulled in tension in its thickness direction.

|.7 Recovery, Recrystallization, and Grain Growth

We have seen that plastic deformation at room temperature causes distortion of the

grains and grain boundaries (leading to anisotropic behavior), a general increase in

strength, and a decrease in ductility. These effects can be reversed, and the properties

of the metal can be brought back to their original levels, by heating the metal to a

specific temperature range for a given period of time-a process called annealing

(described in detail in Section 4.11). Three events take place consecutively during

the heating process:

l. Recovery. During recovery, which occurs at a certain temperature range below

the recrystallization temperature of the metal (described next), the stresses in the

highly deformed regions of the metal piece are relieved. Subgrain boundaries

begin to form (a process called polygonization), with

no significant change in mechanical properties such as

hardness and strength (Fig. 1.13).

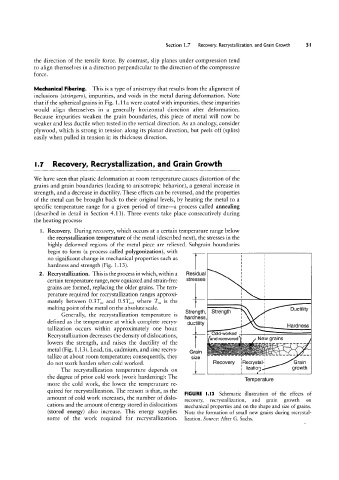

2. Recrystallization. This is the process in which, within a Residual

certain temperature range, new equiaxed and strain-free stresses

grains are formed, replacing the older grains. The tem-

perature required for recrystallization ranges approxi-

mately between 0.3T,,, and 0.5 Tm, where Tm is the

melting point of the metal on the absolute scale.

Strength, Strength Ductmty

Generally, the recrystallization temperature is

hardness,

defined as the temperature at which complete recrys- ductility Hardness

tallization occurs within approximately one hour.

Cold-worked I

Recrystallization decreases the density of dislocations, and recovered New grains

size I

metal (Fig. 1.13). Lead, tin, cadmium, and zinc recrys- Grain fe ear ` 'T' "

it

tallize at about room temperature; consequently, they T "i”` "`

do not work harden when cold worked. Recovery iFIecrysta|-i Grain

The recrystallization temperature depends on Iizatiorl growth

4

the degree of prior cold work (work hardening): The

Temperature

more the cold work, the lower the temperature re-

quired for recrystallization. The reason is that, as the

FIGURE l.l3 Schematic illustration of the effects of

amount of cold work increases, the number of dislo-

recovery, recrystallization, and grain growth on

cations and the amount of energy stored in dislocations mechanical properties and on the shape and size of grains.

(stored energy) also increase. This energy supplies Note the formation of small new grains during recrystal-

some of the work required for recrystallization. lization. Source: After G. Sachs.