Page 188 - Marine Structural Design

P. 188

164 Part II Ultimate Strength

Eccentric Axial Compression Test Using Small Scale Specimens

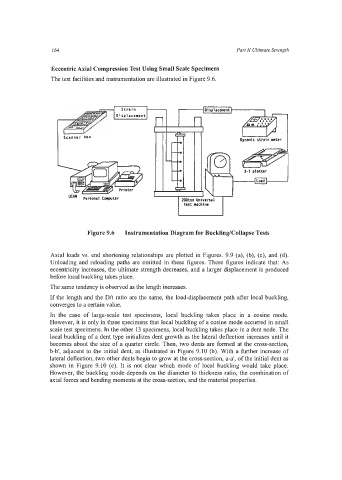

The test facilities and instrumentation are illustrated in Figure 9.6.

u

test uchinr

Figure 9.6 Instrumentation Diagram for BucklingEollapse Tests

Axial loads vs. end shortening relationships are plotted in Figures. 9.9 (a), (b), (c), and (d).

Unloading and reloading paths are omitted in these figures. These figures indicate that: As

eccentricity increases, the ultimate strength decreases, and a larger displacement is produced

before local buckling takes place.

The same tendency is observed as the length increases.

If the length and the D/t ratio are the same, the load-displacement path after local buckling,

converges to a certain value.

In the case of large-scale test specimens, local buckling takes place in a cosine mode.

However, it is only in three specimens that local buckling of a cosine mode occurred in small

scale test specimens. In the other 13 specimens, local buckling takes place in a dent node. The

local buckling of a dent type initializes dent growth as the lateral deflection increases until it

becomes about the size of a quarter circle. Then, two dents are formed at the cross-section,

b-b', adjacent to the initial dent, as illustrated in Figure 9.10 (b). With a further increase of

lateral deflection, two other dents begin to grow at the cross-section, a-a', of the initial dent as

shown in Figure 9.10 (c). It is not clear which mode of local buckling would take place.

However, the buckling mode depends on the diameter to thickness ratio, the combination of

axial forces and bending moments at the cross-section, and the material properties.