Page 190 - Marine Structural Design

P. 190

166 Part II Ultimate Strength

(a) Initial mode

a-a' b-b*

L",!'

(C) Subsequent mode - 2

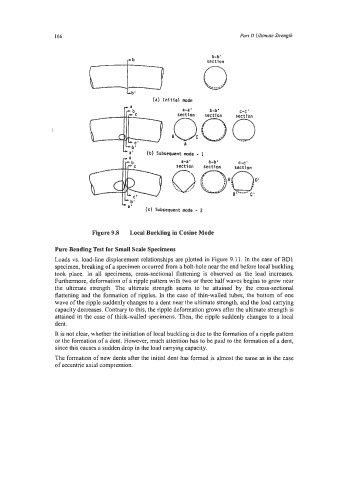

Figure 9.8 Local Buckling in Cosine Mode

Pure Bending Test for Small Scale Specimens

Loads vs. load-line displacement relationships are plotted in Figure 9.11. In the case of BD1

specimen, breaking of a specimen occurred from a bolt-hole near the end before local buckling

took place. In all specimens, cross-sectional flattening is observed as the load increases.

Furthermore, deformation of a ripple pattern with two or three half waves begins to grow near

the ultimate strength. The ultimate strength seems to be attained by the cross-sectional

flattening and the formation of ripples. In the case of thin-walled tubes, the bottom of one

wave of the ripple suddenly changes to a dent near the ultimate strength, and the load carrying

capacity decreases. Contrary to this, the ripple deformation grows after the ultimate strength is

attained in the case of thick-walled specimens. Then, the ripple suddenly changes to a local

dent.

It is not clear, whether the initiation of local buckling is due to the formation of a ripple pattern

or the formation of a dent. However, much attention has to be paid to the formation of a dent,

since this causes a sudden drop in the load carrying capacity.

The formation of new dents after the initial dent has formed is almost the same as in the case

of eccentric axial compression.