Page 362 - Marine Structural Design

P. 362

338 Part III Fatigue and Fracture

the machining has to be performed such that the local stress concentration due to the weld is

removed.

The hot spot stress concept assumes that the effect of the local stress factor, which is due to the

weld profile, should be included in the S-N curves. The stress concentration due to gross

geometry change and local geometry change should be included in the hot spot stress. The

problem with the hot spot stress approach is that the stress gradients are very high in the

vicinity of the weld and plate intersections. Because of the high gradients, the stresses

computed in FEA are extremely sensitive to the finite element mesh size. This mesh sensitivity

results in an inaccurate definition of the hot spot stress in application.

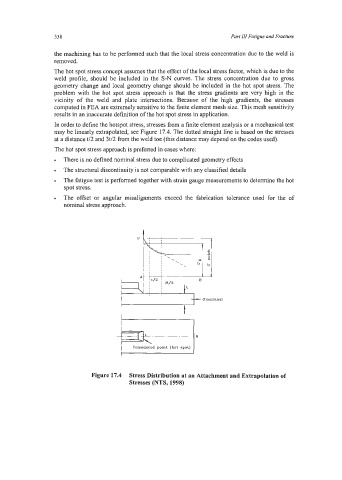

In order to define the hotspot stress, stresses ftom a finite element analysis or a mechanical test

may be linearly extrapolated, see Figure 17.4. The dotted straight line is based on the stresses

at a distance t/2 and 3t/2 from the weld toe (this distance may depend on the codes used).

The hot spot stress approach is preferred in cases where:

There is no defined nominal stress due to complicated geometry effects

The structural discontinuity is not comparable with any classified details

The fatigue test is performed together with strain gauge measurements to determine the hot

spot stress.

The offset or angular misalignments exceed the fabrication tolerance used for the of

nominal stress approach.

.

; ; '\ .

P I b

I ,

I ,

I t

A ' '

Unominal

Considered point (hot spot)

I

Figure 17.4 Stress Distribution at an Attachment and Extrapolation of

Stresses (NTS, 1998)