Page 364 - Marine Structural Design

P. 364

340 Part III Fatigue and Fracture

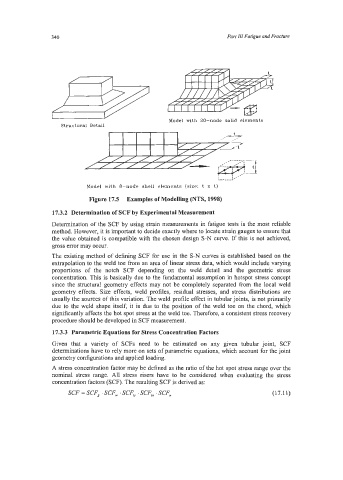

Model with 20-node solid elements

Structural Detail

Model with 8-node shell elements (size: t x t)

Figure 17.5 Examples of Modelling (NTS, 1998)

17.3.2 Determination of SCF by Experimental Measurement

Determination of the SCF by using strain measurements in fatigue tests is the most reliable

method. However, it is important to decide exactly where to locate strain gauges to ensure that

the value obtained is compatible with the chosen design S-N curve. If this is not achieved,

gross error may occur.

The existing method of defining SCF for use in the S-N curves is established based on the

extrapolation to the weld toe from an area of linear stress data, which would include varying

proportions of the notch SCF depending on the weld detail and the geometric stress

concentration. This is basically due to the fundamental assumption in hotspot stress concept

since the structural geometry effects may not be completely separated from the local weld

geometry effects. Size effects, weld profiles, residual stresses, and stress distributions are

usually the sources of this variation. The weld profile effect in tubular joints, is not primarily

due to the weld shape itself, it is due to the position of the weld toe on the chord, which

significantly affects the hot spot stress at the weld toe. Therefore, a consistent stress recovery

procedure should be developed in SCF measurement.

17.3.3 Parametric Equations for Stress Concentration Factors

Given that a variety of SCFs need to be estimated on any given tubular joint, SCF

determinations have to rely more on sets of parametric equations, which account for the joint

geometry configurations and applied loading.

A stress concentration factor may be defined as the ratio of the hot spot stress range over the

nominal stress range. All stress risers have to be considered when evaluating the stress

concentration factors (SCF). The resulting SCF is derived as:

SCF = SCF, . SCF, * SCF,, . SCE;I, . SCF, (17.1 1)