Page 150 - Materials Chemistry, Second Edition

P. 150

137

2.4. The Amorphous State

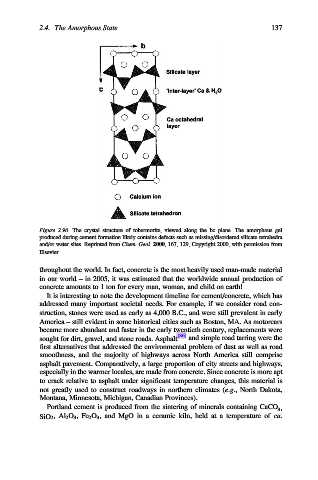

Figure 2.96. The crystal structure of tobermorite, viewed along the bc plane. The amorphous gel

produced during cement formation likely contains defects such as missing/disordered silicate tetrahedra

and/or water sites. Reprinted from Chem. Geol. 2000, 167, 129, Copyright 2000, with permission from

Elsevier.

throughout the world. In fact, concrete is the most heavily used man-made material

in our world – in 2005, it was estimated that the worldwide annual production of

concrete amounts to 1 ton for every man, woman, and child on earth!

It is interesting to note the development timeline for cement/concrete, which has

addressed many important societal needs. For example, if we consider road con-

struction, stones were used as early as 4,000 B.C., and were still prevalent in early

America – still evident in some historical cities such as Boston, MA. As motorcars

became more abundant and faster in the early twentieth century, replacements were

sought for dirt, gravel, and stone roads. Asphalt [86] and simple road tarring were the

first alternatives that addressed the environmental problem of dust as well as road

smoothness, and the majority of highways across North America still comprise

asphalt pavement. Comparatively, a large proportion of city streets and highways,

especially in the warmer locales, are made from concrete. Since concrete is more apt

to crack relative to asphalt under significant temperature changes, this material is

not greatly used to construct roadways in northern climates (e.g., North Dakota,

Montana, Minnesota, Michigan, Canadian Provinces).

Portland cement is produced from the sintering of minerals containing CaCO 3 ,

SiO 2 ,Al 2 O 3 ,Fe 2 O 3 , and MgO in a ceramic kiln, held at a temperature of ca.