Page 212 - Materials Chemistry, Second Edition

P. 212

199

3.2. Metallic Structures and Properties

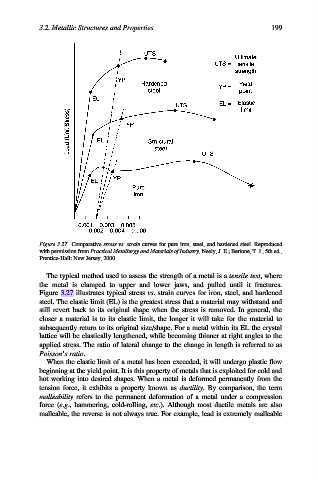

Figure 3.27. Comparative stress vs. strain curves for pure iron, steel, and hardened steel. Reproduced

with permission from Practical Metallurgy and Materials of Industry, Neely, J. E.; Bertone, T. J., 5th ed.,

Prentice-Hall: New Jersey, 2000.

The typical method used to assess the strength of a metal is a tensile test, where

the metal is clamped to upper and lower jaws, and pulled until it fractures.

Figure 3.27 illustrates typical stress vs. strain curves for iron, steel, and hardened

steel. The elastic limit (EL) is the greatest stress that a material may withstand and

still revert back to its original shape when the stress is removed. In general, the

closer a material is to its elastic limit, the longer it will take for the material to

subsequently return to its original size/shape. For a metal within its EL the crystal

lattice will be elastically lengthened, while becoming thinner at right angles to the

applied stress. The ratio of lateral change to the change in length is referred to as

Poisson’s ratio.

When the elastic limit of a metal has been exceeded, it will undergo plastic flow

beginning at the yield point. It is this property of metals that is exploited for cold and

hot working into desired shapes. When a metal is deformed permanently from the

tension force, it exhibits a property known as ductility. By comparison, the term

malleability refers to the permanent deformation of a metal under a compression

force (e.g., hammering, cold-rolling, etc.). Although most ductile metals are also

malleable, the reverse is not always true. For example, lead is extremely malleable