Page 215 - Materials Chemistry, Second Edition

P. 215

202 3 Metals

Table 3.3. General Types and Properties of Stainless Steels

Type Concentration Properties/applications

Martensitic 11–20 wt.% Cr High hardness, magnetic/cutlery, blades, surgical instruments,

0.15–0.75 wt.% C valves, springs

Austenitic 16–26 wt.% Cr High and low temperature resistance, ductility, superior corrosion

35 wt.% Ni resistance/kitchen sinks, ovens, reaction vessels, food processors,

20 wt.% Mn gutters

Ferritic 10.5–30 wt.% Cr Magnetic, inexpensive/automotive exhaust and fuel lines, cooking

<1 wt.% C, N, Ni utensils, bank vaults, washing machines, dishwashers

Duplex 18–26 wt.% Cr Weldable, high tensile strength, Cl ion resistance (acidic

(austenitic– 4–7 wt.% Ni environments)/desalination plants, food pickling plants,

ferritic) 2–3 wt.% Mo petrochemical plants, pulp and paper industries

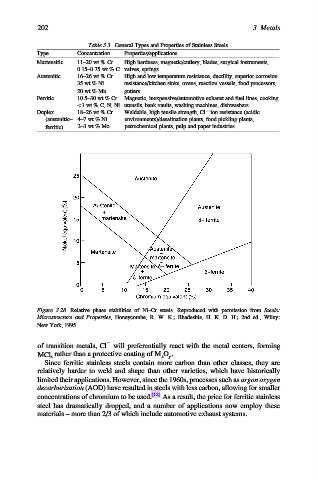

Figure 3.28. Relative phase stabilities of Ni–Cr steels. Reproduced with permission from Steels:

Microstructure and Properties, Honeycombe, R. W. K.; Bhadeshia, H. K. D. H.; 2nd ed., Wiley:

New York, 1995.

of transition metals, Cl will preferentially react with the metal centers, forming

MCl x rather than a protective coating of M x O y .

Since ferritic stainless steels contain more carbon than other classes, they are

relatively harder to weld and shape than other varieties, which have historically

limited their applications. However, since the 1960s, processes such as argon oxygen

decarburization (AOD) have resulted in steels with less carbon, allowing for smaller

concentrations of chromium to be used. [12] As a result, the price for ferritic stainless

steel has dramatically dropped, and a number of applications now employ these

materials – more than 2/3 of which include automotive exhaust systems.