Page 208 - Mechanical Engineer's Data Handbook

P. 208

196 MECHANICAL ENGINEER’S DATA HANDBOOK

Cutting fluid applications (continued)

Group Description Advantages

Straight oils Mineral or fatty oils (lard, sperm, Good lubricant. Often unstable.

olive, neat’s foot, rape, etc.) alone

or compounded

Sulphurized EP oils Straight oils with sulphur, zinc oxide Average coolant. Good lubricant.

or other additives (0.2-0.8%S) Pressure resistant. Prevents welding

of chip on tool

Sulphochlorinated EP oils Mineral and fatty oil blends with More efficient than sulphurized oils.

sulphur and chlorine additives For most arduous conditions.

Highly resistant to welding of chip

on tool

Chlorinated materials Carbon tetrachloride and Very good EP fluid. Highly

trichlorethylene alone or blended dangerous to use

with oils

Gases and vapours Air, oil mist, CO, Limited cooling power. Chip

dispersed

EP, extreme pressure.

5.8 Casting

Casting is the forming of metal or plastic parts by removing it from the mould. Further processing is

introducing the liquid material to a suitably shaped usually required.

cavity (mould), allowing it to solidify, and then

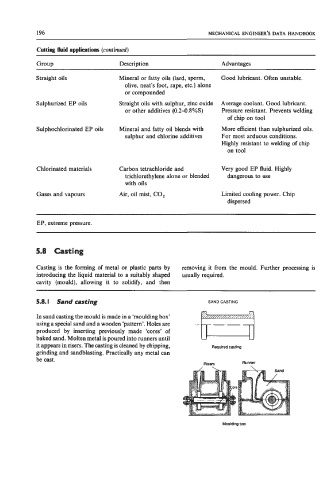

5.8.1 Sand casting SAND CASTING

In sand casting the mould is made in a ‘moulding box’

using a special sand and a wooden ‘pattern’. Holes are .-

produced by inserting previously made ‘cores’ of

baked sand. Molten metal is poured into runners until

it appears in risers. The casting is cleaned by chipping, Required casting

grinding and sandblasting. Practically any metal can

be cast.

Risers Runner

Moulding box