Page 206 - Mechanical Engineer's Data Handbook

P. 206

194 MECHANICAL ENGINEER'S DATA HANDBOOK

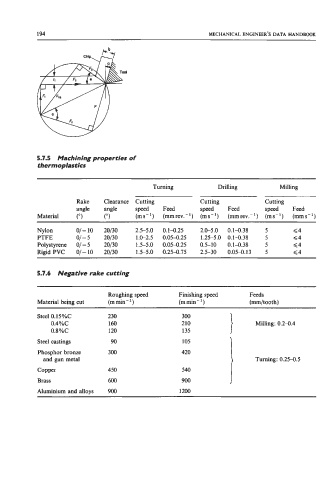

5.7.5 Machining properties of

thermoplastics

Turning D r i 11 in g Milling

Rake Clearance Cutting Cutting Cutting

angle angle speed Feed speed Feed speed Feed

Material ("1 ("1 (ms-') (mmrev.-') (ms-') (mmrev.-') (ms-') (mms-')

Nylon 01-10 20130 2.1-5.0 0.1-0.25 2.0-5.0 0.1-0.38 5 <4

PTFE 01-5 20130 1.0-2.5 0.05-0.25 1.25-5.0 0.1-0.38 5 <4

Polystyrene Of - 5 20130 1.5-5.0 0.05-0.25 0.5-10 0.1-0.38 5 94

Rigid PVC 01-10 20130 1.5-5.0 0.25-0.75 2.5-30 0.05-0.13 5 <4

5.7.6 Negative rake cutting

Roughing speed Finishing speed Feeds

Material being cut (m min- ') (mmin-I) (mmftoot h)

Steel 0.15%c 230 300

0.4%c 160 210 Milling: 0.2-0.4

O.8%C 1 20 135

Steel castings 90 105

Phosphor bronze 300 420

and gun metal Turning: 0.25-0.5

Copper 450 540

Brass 600 900

Aluminium and allovs 900 1200