Page 202 - Mechanical Engineer's Data Handbook

P. 202

190 MECHANICAL ENGINEER’S DATA HANDBOOK

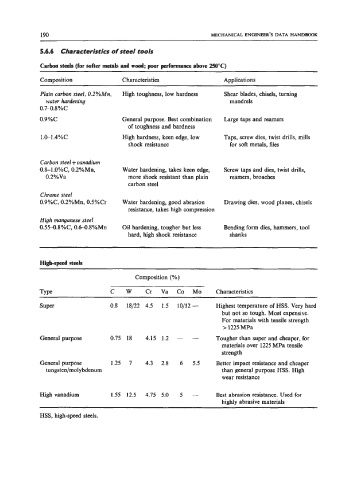

1.6.6 Characteristics of steel tools

Carboo steels (for softer metals and wood; poor perfomace above 250°C)

Composition Characteristics Applications

Plain carbon steel, O.Z%Mn, High toughness, low hardness Shear blades, chisels, turning

water hardening mandrels

0.7-0.8%c

0.9%c General purpose. Best combination Large taps and reamers

of toughness and hardness

High hardness, keen edge, low Taps, screw dies, twist drills, mills

shock resistance for soft metals, files

Carbon steel + vanadium

0.8-1 .O%C, 0.2%Mn, Water hardening, takes keen edge, Screw taps and dies, twist drills,

0.2%Va more shock resistant than plain reamers, broaches

carbon steel

Chrome steel

0.9%C, 0.2%Mn, O.S%Cr Water hardening, good abrasion Drawing dies, wood planes, chisels

resistance, takes high compression

High manganese steel

OSM.8%C, 0.6-0.8Y0Mn Oil hardening, tougher but less Bending form dies, hammers, tool

hard, high shock resistance shanks

High-speed steels

Composition (%)

C W Cr Va Co Mo Characteristics

- ~-

~ ~~

Super 0.8 18/22 4.5 1.5 10112 - Highest temperature of HSS. Very hard

but not so tough. Most expensive.

For materials with tensile strength

=- 1225 MPa

General purpose 0.75 18 4.15 1.2 - - Tougher than super and cheaper, for

materials over 1225 MPa tensile

strength

General purpose 1.25 7 4.3 2.8 6 5.5 Better impact resistance and cheaper

tungsten/molybdenum than general purpose HSS. High

wear resistance

High vanadium 1.55 12.5 4.75 5.0 5 - Best abrasion resistance. Used for

hinhlv abrasive materials

HSS, high-speed steels.