Page 199 - Mechanical Engineer's Data Handbook

P. 199

MANUFACTURING TECHNOLOGY 187

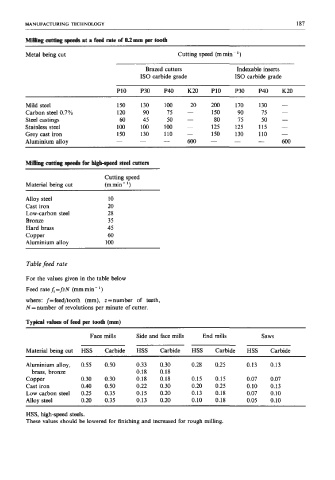

Milling cutting speeds at a fed rate of 0.2mm per tootb

Metal being cut Cutting speed (mmin-')

Brazed cutters Indexable inserts

IS0 carbide grade IS0 carbide grade

P10 P30 P40 K20 P10 P30 P40 K20

Mild steel 150 130 100 20 200 170 130 -

Carbon steel 0.7% 120 90 75 - 150 90 75 -

Steel castings 60 45 50 - 80 75 50 -

Stainless steel 100 100 100 - 125 125 115 -

Grey cast iron 150 130 110 - 150 130 110 -

Aluminium alloy - - - 600- - - 600

Milling cutting speeds for hishspeea steel cutters

Cutting speed

Material being cut (m min - ' )

Alloy steel 10

Cast iron 20

Low-carbon steel 28

Bronze 35

Hard brass 45

Copper 60

Aluminium alloy 100

Table feed rate

For the values given in the table below

Feed rate f, =fzN (mm min- ')

where: f=feed/tooth (mm), z=number of teeth,

N =number of revolutions per minute of cutter.

Typical values of feed per tooth (mm)

Face mills Side and face mills End mills Saws

Material being cut HSS Carbide HSS Carbide HSS Carbide HSS Carbide

Aluminium alloy, 0.55 0.50 0.33 0.30 0.28 0.25 0.13 0.13

brass, bronze 0.18 0.18

Copper 0.30 0.30 0.18 0.18 0.15 0.15 0.07 0.07

Cast iron 0.40 0.50 0.22 0.30 0.20 0.25 0.10 0.13

Low carbon steel 0.25 0.35 0.15 0.20 0.13 0.18 0.07 0.10

Alloy steel 0.20 0.35 0.13 0.20 0.10 0.18 0.05 0.10

HSS, high-speed steels.

These values should be lowered for finishing and increased for rough milling.