Page 194 - Mechanical Engineer's Data Handbook

P. 194

182 MECHANICAL ENGINEER’S DATA HANDBM~K

Drill angles

Point angle Lip clearance

Material Helix angle (“1 (“1

~-

~ ~ ~~ ~ ~ ~

Aluminium alloy Quick 140 12-15

Magnesium alloy Standard 100 12-15

Brass Slow 130 10-12

Copper Quick 125 12-15

Bakelite Slow 30 12-15

Manganese steel Slow 130 7-10

5.4 Milling

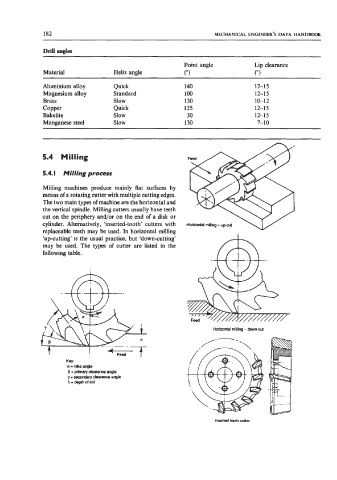

5.4. I Milling process

Milling machines produce mainly flat surfaces by

means of a rotating cutter with multiple cutting edges.

The two main types of machine are the horizontal and

the vertical spindle. Milling cutters usually have teeth

cut on the periphery and/or on the end of a disk or

cylinder. Alternatively, ‘inserted-tooth’ cutters with

replaceable teeth may be used. In horizontal milling

‘upcutting’ is the usual practice, but ‘down-cutting’

may be used. The types of cutter are listed in the

following table.

Feed

Horizontal milling - dowrrcui