Page 192 - Mechanical Engineer's Data Handbook

P. 192

180 MECHANICAL ENGINEER'S DATA HANDBOOK

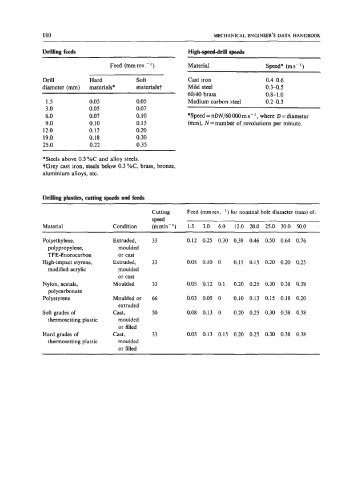

Drilling feeds Higb-speeddrill sped

Feed (mm rev.- ') Material Speed* (ms-')

Drill Hard Soft Cast iron O.M.6

diameter (mm) materials* materials? Mild steel 0.3-4.5

60140 brass 0.8-1.0

1.5 0.05 0.05 Medium carbon steel 0.2-0.3

3 .O 0.05 0.07

6 .O 0.07 0.10 *Speed = nDN/60 OOO m s- ' , where D = diameter

9.0 0.10 0.15 (mm), N = number of revolutions per minute.

12.0 0.12 0.20

19.0 0.18 0.30

25.0 0.22 0.35

~ ~

*Steels above 0.3 %C and alloy steels.

tGrey cast iron, steels below 0.3 %C, brass, bronze,

aluminium alloys, etc.

Drilling plastics, cutting speeds and feeds

Cutting Feed (mmrev.-') for nominal hole diameter (mm) of:

speed

Material Condition (mmin-') 1.5 3.0 6.0 12.0 20.0 25.0 30.0 50.0

Polyethylene, Extruded, 33 0.12 0.25 0.30 0.38 0.46 0.50 0.64 0.76

polypropylene, moulded

TFE-fluorocarbon or cast

High-impact styrene, Extruded, 33 0.05 0.10 0 0.15 0.15 0.20 0.20 0.25

modified acrylic moulded

or cast

Nylon, acetals, Moulded 33 0.05 0.12 0.1 0.20 0.25 0.30 0.38 0.38

polycarbonate

Polystyrene Moulded or 66 0.03 0.05 0 0.10 0.13 0.15 0.18 0.20

extruded

Soft grades of Cast, 50 0.08 0.13 0 0.20 0.25 0.30 0.38 0.38

thermosetting plastic moulded

or filled

Hard grades of Cast, 33 0.05 0.13 0.15 0.20 0.25 0.30 0.38 0.38

thermosetting plastic moulded

or filled