Page 191 - Mechanical Engineer's Data Handbook

P. 191

MANUFACTURING TECHNOLOGY 179

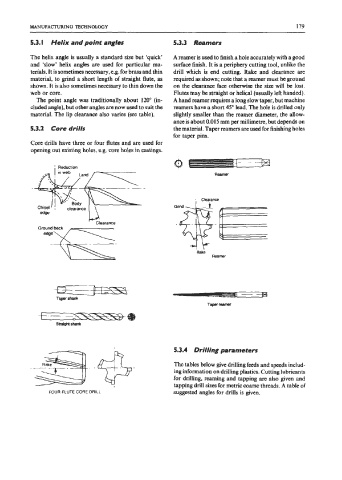

5.3. I Helix and point angles 5.3.3 Reamers

The helix angle is usually a standard size but 'quick' A reamer is used to finish a hole accurately with a good

and 'slow' helix angles are used for particular ma- surface finish. It is a periphery cutting tool, unlike the

terials. It is sometimes necessary, e.g. for brass and thin drill which is end cutting. Rake and clearance are

material, to grind a short length of straight flute, as required as shown; note that a reamer must be ground

shown. It is also sometimes necessary to thin down the on the clearance face otherwise the size will be lost.

web or core. Flutes may be straight or helical (usually left handed).

The point angle was traditionally about 120" (in- A hand reamer requires a long slow taper, but machine

cluded angle), but other angles are now used to suit the reamers have a short 45" Lead. The hole is drilled only

material. The lip clearance also varies (see table). slightly smaller than the reamer diameter, the allow-

ance is about 0.015 mm per millimetre, but depends on

5.3.2 Core drills the material. Taper reamers are used for finishing holes

for taper pins.

Core drills have three or four flutes and are used for

opening out existing holes, e.g. core holes in castings.

@I - -

: Reduction

IJ Clearance

Rake

Reamer

Taper shank

5.3.4 Drilling parameters

The tables below give drilling feeds and speeds includ-

.___

T- ing information on drilling plastics. Cutting lubricants

for drilling, reaming and tapping are also given and

tapping drill sizes for metric coarse threads. A table of

FOUR FLUTE CORE DRILL suggested angles for drills is given.