Page 189 - Mechanical Engineer's Data Handbook

P. 189

MANUFACTURING TECHNOLOGY 177

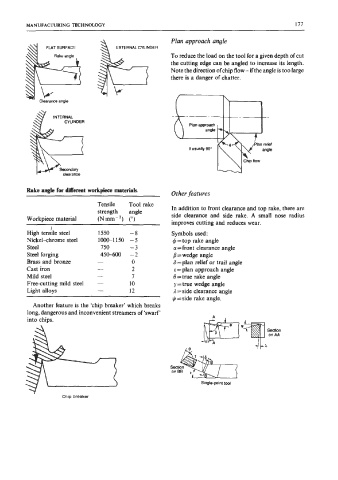

Plan approach angle

EXTERNAL CYLINDER

FLAT SURFACE EXTERNAL CYLINDER

To reduce the load on the tool for a given depth of cut

the cutting edge can be angled to increase its length.

Note the direction of chip flow - if the angle is too large

there is a danger of chatter.

k

Clearance angle

Clearance angle

INTERNAL

CYLINDER Plan approach

angle

e usually 90"

I Chip now

IC clearance

Rake angle for Merent workpiece materials

Other features

Tensile Tool rake

strength angle In addition to front clearance and top rake, there are

side clearance and side rake. A small nose radius

Workpiece material (Nmm-2) (")

improves cutting and reduces wear.

I

High tensile steel 1550 -8 Symbols used:

Nickel-chrome steel loo(r1150 -5 4-top rake angle

Steel 750 -3 a =front clearance angle

Steel forging 450-600 -2 /3 = wedge angle

Brass and bronze - 0 S =plan relief or trail angle

Cast iron - 2 E = plan approach angle

Mild steel - 7 8 =true rake angle

Free-cutting mild steel - 10 y = true wedge angle

Light alloys - 12 1 =side clearance angle

$ =side rake angle.

Another feature is the 'chip breaker' which breaks

long, dangerous and inconvenient streamers of 'swarf'

into chips.

Single-point tool

Chip breaker